Feb 17th 2026

What is the Water Hammer Effect?

The water hammer effect, or also simply known as water hammer, is a common plumbing phenomenon that can be both startling and damaging. If you've ever heard a loud, knocking sound in your pipes after shutting off a faucet or when your washing machine finishes its cycle, you've likely heard water hammer in action. A water hammer, especially when left untreated, can cause damage ranging from minimal to dangerous.

We’ve compiled a comprehensive guide to help you understand the water hammer effect more thoroughly, along with potential causes, solutions, and preventative measures you can take to combat water hammer.

What is a Water Hammer?

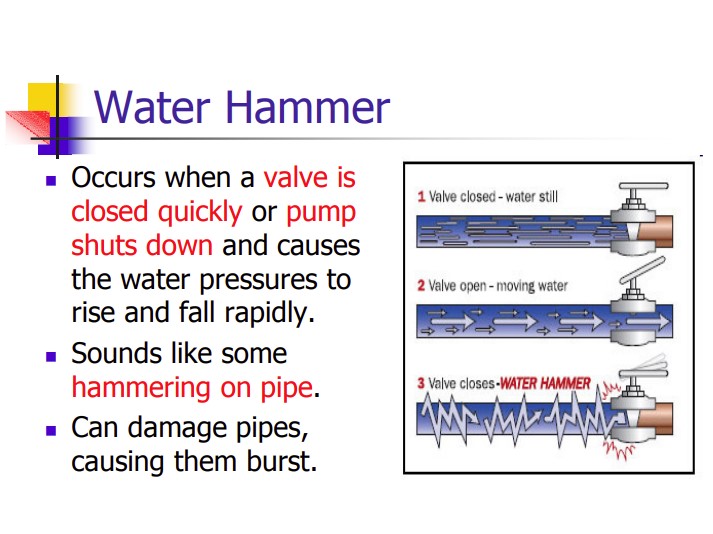

Water hammer is the more commonly known term for the phenomenon called hydraulic shock or hydraulic surge. The water hammer effect results from a water pressure surge in your pipes, often occurring after an abrupt direction change, burst from a previously clogged pipe, or a sudden valve shutdown from within the plumbing system.

The backup causes a clamoring noise, much like a hammer does as it pounds against an object, hence the commonly known name, water hammer.

What Causes Water Hammer?

The water hammering effect is a fairly common problem. It happens when a pipeline system shuts off too abruptly. The valve shuts too quickly for what's already rushed through the system to withstand. This phenomenon leads to a buildup of pressurized water.

Since the water continued to surge at full capacity, it hit the closed valve — like hitting a brick wall. When the water makes an impact on the valve, it sends a shockwave through the pipe system.

Visualization and brief explanation a water hammer

Hydraulic shock can also occur when the water buildup has to make a sudden direction change, such as a curve in the pipe. When there’s an accumulation rushing toward a direction and must make a sharp turn, it may result in the water hammer effect.

The effect doesn’t only occur to water-centric pipe systems; it happens with some gas or steam systems too. In these systems, a water hammer results from condensation accumulation.

As the condensation grows, it becomes more hazardous as the resulting slug travels at the same standard steam speed. However, because the condensation is denser and closer to a solid, requiring a lesser traveling speed, it will create a more substantial impact.

How Do You Know If You Have Water Hammer?

You may not think anything of this phenomenon at first, but you’ll most likely notice a loud hammering or thumping noise as if banging pipes together. The sound is the shockwave from water buildup hitting the closed valve and the pipes trying to absorb the impact.

When you run your water system whether a sink, shower, hose, or what have you, you won’t hear any sound other than the smooth rushing water flowing through the plumbing system. If you hear the loud thud or banging pipes in your walls, you most likely have a water hammer.

What Happens if You Don’t Fix Water Hammer?

You may not think anything of the knocking noises at first, but the sound it makes is just a precursor to the damage it can cause, even after just a single occurrence depending on the state of your plumbing system.

Possible damage from a water hammer includes:

Pressure Gauge and Flow Meter Damage

Even if your pressure gauge is set to the correct levels and works correctly, a water hammer can still damage it. The water hammer’s resulting shockwave from the pressure buildup shoots straight to the pressure gauge, where it spikes to a damaging level.

Blown Diaphragm

A blown diaphragm also results from the immense pressure that accompanies the water hammer effect. In a pressure tank, the diaphragm separates air and water. When the diaphragm blows, the pressure system cannot regulate water flow, meaning you might get stuck with a constant water flow.

Gasket Damage

Pipe joint gaskets were not built to withstand high-pressure levels. When a water hammer occurs, the gaskets may weaken or spurt leaks as a means of absorbing the effect’s shock.

Erosion

Over time, the water logjam can slowly work away at the pipe system. The condensation or water can weather and erode the pipes making them weak and thin the materials allowing for leaks. Erosion can also weaken the joints where pipes are joined together making them unstable and giving them the potential to burst literally at the seam.

Water Hammer Can Burst Pipes?

Yes. A water hammer can cause a pipe rupture which results from a break in the pipe system. This effect occurs if the pipe is not equipped to handle the pressure and instead ruptures or bursts. This can also happen when the pipe joints weaken from the pressure of the hydraulic shock.

The water hammer sound comes from the physical pipe vibration. If the pressure is too great and the pipes too weak, the vibrating can result in banging pipes that are more likely to burst. A pipe rupture or burst is one of the more extreme, dangerous causes of a water hammer.

How to Fix Water Hammer

Once a water hammer occurs, it’s not irreversible. There are a few solutions you can implement to fix water hammer, such as calling a professional to assess the situation. You can also replace your pipes with a stronger, more durable alternative and/or consider changing the type of electric valves if they are part of your system.

Do Not Ignore the Problem

A water hammer may just sound like knocking pipes, but the sound is just a signifier of the damage happening within the system. If you notice the sound, do not carry on as if it will go away on its own, chances are it won’t. Instead, check out the pipe system and your pressure tank for damage or water hammer signs.

From there, you should call a plumber or other professional to assess the damage and required solution, which may be more complicated than you can handle on your own.

Replace Your Pipes

Water hammer may result from a less than adequate pipe system. If a water hammer occurs, one solution is to replace your pipes entirely with ones that have more support, high-quality materials, air chambers, and no slam check valves.

Change Your Valve Type

A common valve used in systems prone to water hammer are electric solenoid valves. These are great options for quickly opening and closing valve ports, but that also leads them to be more susceptible to water hammer. If your system does not need to immediately stop the flow of water or other media, a manual or an electric/motorized ball valve could be a better option. Ball valves open and close slower than a solenoid valve, which prevents the liquid or gas from building up pressure so quickly in the pipes.

Click here to learn more about the difference between solenoid valves and motorized ball valves to choose the best option for your system.

How to Prevent Water Hammer

It’s one thing to learn how to fix a water hammer if it occurs, but you can take your measures a step further in learning how to stop water hammer from ever happening. Preventing water hammer involves a little check-up on your pipes and making sure they are in pristine condition so that the effect never occurs. It also involves implementing new materials and valves to minimize the chances.

Pipe Support

If your pipe system is weak or sagging, it may be prone to pooling. Pooling is when water accumulates in the lower portions of the pipes. When the pressure flows through the system, this water slug from the sagging pipes can result in the water hammer effect. You can install a support system to combat this potential hazard and keep your pipes sturdy.

Air Chambers

Most pipe systems should come with an air chamber, which provides a little bit of cushion between water and the valve to absorb shock and pressure from the water flow. Pipes without air chambers may succumb to the water hammering effect more easily. Check your pipes and have a system with air chambers installed to prevent the water hammer effect.

No Slam Check Valves

One of the water hammer's causes is shutting a valve too quickly. You can get no slam check valves installed to prevent any abrupt shutting, thereby reducing the likelihood of a water hammer.

Install Steam Lines with a Gradual Slope

The water hammer effect in steam lines occurs from condensation accumulation and pooling. You can get a steam line installed with a gradual slope toward the flow as a way to combat the water hammer effect.

Final Thoughts on Water Hammer

Water hammer is more than just a noisy annoyance—it's a potential threat to your plumbing system. By implementing the right preventative measures and using advanced valve technology, you can protect your home and save money on repairs.

FAQs About Water Hammer

What is the water hammer effect?

The water hammer effect is a pressure surge or wave that occurs when a fluid in motion, such as water, is forced to stop or change direction suddenly. This sudden change in flow can create a loud banging or hammering noise in the pipes.

Can water hammer damage pipes?

Yes, the water hammer effect can potentially damage pipes, fittings, and other plumbing components. The sudden pressure surge can cause pipes to vibrate, loosen, or even burst, leading to leaks and other issues.

What causes water hammer in pipes?

Water hammer is caused by the sudden stop or redirection of fluid flow within pipes, often due to quick-closing valves or sharp turns in the piping.

How can I fix water hammer in my home?

To fix water hammer, you first need to know the cause. It may be worth calling a plumber to assess the situation and recommend the appropriate solution. Common fixes include installing water hammer arrestors, reducing water pressure, securing loose pipes, replacing your pipes with more shock-resistant material, adjusting the valves, or installing a different type of valve in your system.

How can I prevent water hammer?

There are several ways to prevent water hammer:

- Install air chambers or water hammer arrestors at key points in the plumbing system to absorb the pressure shock.

- Use slow-closing valves like electric or manual ball valves instead of fast-acting valves to reduce the chance of sudden pressure changes.

- Secure any loose pipes to prevent movement and noise.

- Maintain a consistent flow rate in the plumbing system to avoid sudden stops or changes in water flow.