Jul 10th 2024

Comparing L-Type vs. T-Type 3-Way Ball Valves

Designed with three ports, 3way valves allow for the diversion and mixing of flow paths. This configuration is versatile for many applications, but before you buy yourself a 3-way ball valve, you should check which port configuration would be best for your system.

There are two different types of 3-way ball valves configurations. They are either L-type or T-type, which is determined by the shape of the bore in the whole. Each has their own characteristics that make them better than the other for specific uses. In this article, we’ll go over the key differences between L-type and T-type 3-way ball valves which should help you make a more informed decision when searching for a valve to install in your system.

L-Type 3-Way Ball Valves

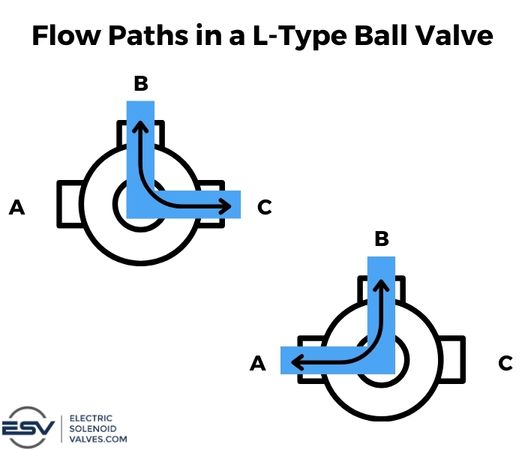

L-type (L-port) ball valves have an L-shaped flow path that can be used to divert fluid at a 90-degree angle. The design includes a ball with a bore shaped like a capital 'L'. This shape allows the fluid to flow through two of the three ports while the third port remains closed. This configuration is ideal for switching the flow between two different outlets or shutting off the flow entirely.

Flow Paths and Configurations:

L-type ball valves have one inlet port and two outlet ports. Turning the valve handle (or activating the actuator for electric 3-way ball valves) rotates the ball inside to align the bore with one of the outlet ports. Each quarter turn changes the flow path allowing you to:

- Shut off the flow

- Divert the media flow between the left port and the center port

- Divert the media flow between the right port and the center port

Common Applications

The simplicity of L-type valves make them ideal for applications where basic flow diversion or shut-off is required. Some common uses include:

- HVAC systems: Directing coolant flow.

- Industrial processes: Controlling the direction of chemical flows.

- Irrigation systems: Switching between water sources or zones.

Pros and Cons of L-type Ball Valves:

| Advantages | Disadvantages |

|

|

|

|

|

T-Type 3-Way Ball Valves

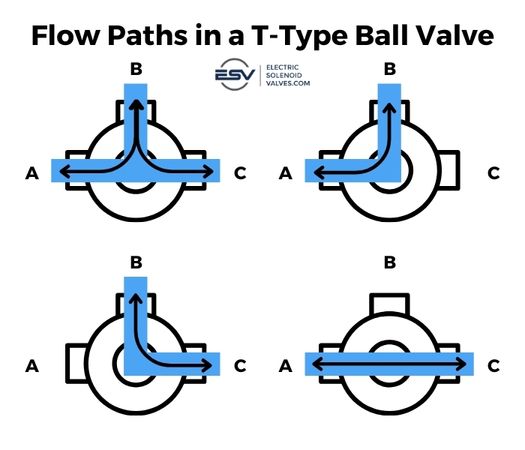

T-type (T port) 3-way ball valves have a ball inside with a capital 'T'-shaped bore. The T-type configuration can direct flow between any of the three ports. This allows more complex flow patterns, including the ability to mix fluids.

Flow Paths and Configurations

The design and operation of T-type valves allow for multiple flow configurations. Each quarter turn allows you to:

- Shut off the flow

- Divert the media flow between the left port and the center port

- Divert the media flow between the right port and the center port

- Open all three ports at once

Common Applications

The unique flow capabilities of T-type valves open up a wider range of applications than L-type valves. These include:

- Mixing hot and cold water: Achieving precise temperature control in plumbing systems.

- Chemical processing: Blending different chemicals in controlled proportions.

- Industrial processes: Controlling flow and mixing in various applications.

Pros and Cons of T-Type Ball Valves:

| Advantages | Disadvantages |

|

|

|

|

|

Key Differences Between L-Type and T-Type 3-Way Ball Valves

L-type and T-type 3-way ball valves differ significantly in their flow patterns and configurations.

Flow Patterns and Configurations

- L-Type: Primarily designed for diverting flow at a 90-degree angle. They offer two flow paths: one straight through and one diverted at a right angle. L-type valves are not suitable for mixing fluids.

- T-Type: Offer greater flexibility with three flow paths. They can divert flow like L-type valves but also have a unique mixing capability, allowing fluids from two inlets to combine in a single outlet.

Typical Use Cases and Limitations

L-Type:

- Use Cases: For applications where fluid needs to be diverted between two different pipelines or completely shut off. Commonly installed in irrigation systems, water distribution networks, and simple industrial processes.

- Limitations: Limited to simple diverting tasks and not suitable for mixing fluids, which restricts its use in more complex systems.

T-Type:

- Use Cases: Mixing fluids, blending chemicals, and for systems requiring precise flow control. Commonly used in HVAC systems, chemical processing, and water treatment plants.

- Limitations: Due to its complexity, these are generally more expensive and require more planning and configuration to fit a system.

Installation and Maintenance Considerations

L-type valves are generally easier to install and maintain due to their simpler design. They require less planning regarding flow patterns, making them suitable for straightforward applications. T-type valves require more careful planning and installation for proper operation in complex systems. Maintenance can also be more demanding due to the additional pathways and potential for mixing fluids, which may require more frequent inspections and servicing.

| Feature | L-Type | T-Type |

|

Flow Pattern |

|

|

|

Flow Capacity |

|

|

|

Mixing Capability |

|

|

|

Cost |

|

|

|

Complexity |

|

|

|

Ideal Applications |

|

|

Choosing the Right Valve

Factors to Consider

When selecting between L-type and T-type 3-way ball valves, consider the following factors:

- Desired Flow Pattern: Determine if you need a valve for simple diverting or if mixing and more complex flow paths are required.

- Flow Capacity Requirements: Assess the flow capacity needed for your application to ensure optimal performance.

- Budget: Evaluate the project budget and determine if the additional cost of a T-type valve is justified.

- Complexity of the Application: Consider the overall complexity of the system and whether the advanced capabilities of a T-type valve are necessary.

When to Choose L-Type

Opt for an L-type valve for simple diverting and shut-off applications or where cost is a primary concern. These valves are ideal for straightforward systems that do not require fluid mixing or complex flow control.

When to Choose T-Type

Choose a T-type valve for applications involving mixing, blending, or requiring precise flow control and higher flow capacity. These valves are suitable for more complex systems where versatility and advanced flow management are essential.

Control Your Flow with ElectricSolenoidValves.com

At ElectricSolenoidValves.com, offer a range of both electric and manual 3-way ball valves to suit your specific needs. Whether you're looking for the simplicity of an L-type valve or the versatility of a T-type, we have you covered.

Here's why you should choose ElectricSolenoidValves.com for your valve needs:

- Extensive In-Stock Inventory: We keep a large stock of all of our valves, ensuring you can find the exact model you need without delay.

- Rapid Shipping: We understand that time is critical when it comes to flow control. That's why we process and ship all orders within one business day. Plus, we offer fast shipping options to get your valves to you as quickly as possible.

- Expert Support: Still have questions? Our team of valve experts is ready to assist you. Whether you prefer a phone call, web chat, or email, we're here to provide the guidance you need to make the right choice.

Not sure which port you need? Contact us with your media, line size, and desired flow paths, and we’ll recommend the right L-port or T-port 3-way ball valve for your system.

Frequently Asked Questions (FAQs)

Q: What are the main differences between L-type and T-type 3-way ball valves?

A: The main difference is the flow patterns created by the different shape of the bore in the ball. L-type valves have a capital L shaped bore to divert flow between two ports at a 90-degree angle. T-type valves have a capital T shaped bore that can mix fluids and direct flow between all three ports.

Q: Can L-type valves be used for mixing applications?

A: No, L-type valves are not designed for mixing fluids. They are primarily designed for diverting flow and not suitable for mixing applications. If you need to mix fluids, a T-type valve is the appropriate choice.

Q: What materials are 3-way ball valves made of?

A: 3-way ball valves can be made from various materials, including stainless steel, brass, PVC, and CPVC. The choice of material depends on the application and the fluids being handled.

Q: Are 3-way ball valves only manually operated?

A: They are not. Electric 3-way ball valves are also available for systems that require automation or remote control.