Jun 2nd 2021

How Does a Solenoid Work?

Solenoids are everywhere in your daily life, from starting your car to ringing your doorbell. These simple devices quietly power countless everyday actions. But what exactly is a solenoid, and how does it work? In this post we’ll break down the basics for you.

What Is a Solenoid?

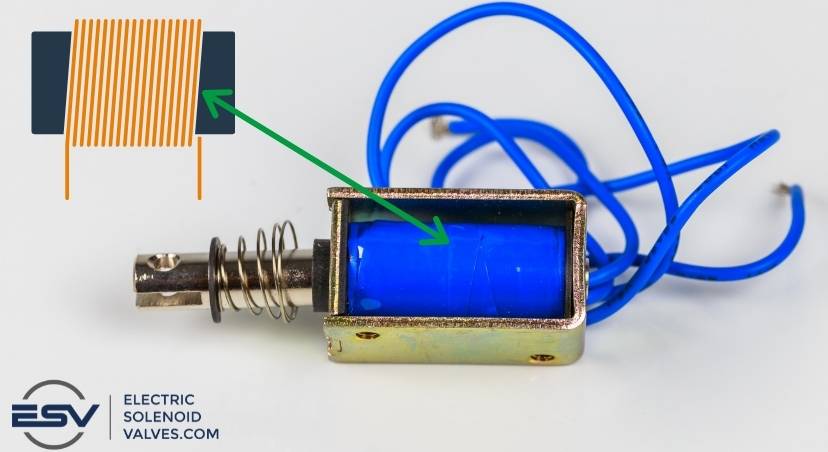

A solenoid is an electromechanical device that uses a coil of wire, a movable core, and electrical current to create a magnetic field that produces mechanical motion. You can use this motion to perform a variety of tasks, from opening and closing valves to starting your car.

Key Components of a Solenoid:

- Coiled Wire: Generates the magnetic field when electricity flows through it.

- Movable Core (Armature): The component that moves in response to the magnetic field, translating electrical energy into mechanical motion.

- Electricity: Powers the solenoid, enabling the magnetic field to form and drive the core's movement.

Working Principle - How a Solenoid Works

At the simplest level, a solenoid is a length of wire coiled around a core. The core often has two parts-- a stationary core and a moveable one (the armature). The two parts are spring-loaded.

When electrical current flows through the wire, it creates a magnetic field. This field moves the armature away from the stationary core or toward it. The construction of a solenoid determines the direction When the current stops, the spring snaps the armature back into its original position.

Step-by-Step Process of How a Solenoid Works:

- Electric Current Flows: When powered, an electric current runs through the solenoid’s wire coil, creating a magnetic field.

- Magnetic Field Forms: This magnetic field exerts force on the armature, which moves in response. In a linear solenoid, this motion is back and forth, while in a rotary solenoid, it rotates.

- Mechanical Movement Happens: The armature’s motion is used to open or close valves, complete an electrical circuit, or engage a mechanical system.

- Deactivation: Once the electric current stops, a spring returns the armature to its original position, resetting the solenoid for the next cycle.

For example, in a car's ignition system, these parts work together to move the armature. This movement completes the circuit that starts your engine. When you let go of the key, the solenoid turns off. The armature goes back to its original position. The circuit is then broken. This way, your car’s ignition stops trying to start the engine, as it’s already running.

While a solenoid uses electromagnetism, it is not itself an electromagnet. It only uses electromagnetism to do its work. Despite this, many people use the terms interchangeably.

For a visual reference on solenoids, see the video below:

A solenoid gets dissected starting at the 5:40 mark, allowing you to see that it is nothing more than a coil of copper wire. It takes the electrical current to make the solenoid work.

Find an automotive-specific video here:

In this video, you will find more information about a car's starter solenoid. You will see what it looks like inside. You will also learn what causes these units to fail. This includes why the clicking noise your car makes when it won’t start shows a bad solenoid.

What Is a Solenoid Valve?

Solenoid valves are just like any other valve in that they regulate the flow of gasses or liquids. The presence of a solenoid in them allows those valves to open or close via electricity.

You can find these types of valves in two different defaults: normally open and normally closed.

In a solenoid valve’s resting position-- off-- no current runs through the wires, and the movable core rests against the base of the valve. By doing so, it seals the valve, as the liquid or gas behind it cannot get through.

Sending electricity through the coil of wire creates the magnetic field, that field causes the core to lift up, and the liquid or gas can now pass freely through the valve. Turning off the electricity drops the core back down, closing the valve and cutting off the gas or liquid flow. This is the function of a normally closed valve, which stays closed until electricity is used to open the valve.

A normally open solenoid valve uses the same fundamentals, but is designed to work in reverse. When in the off position, the core remains in the up position, allowing media to flow through the open valve. Powering the valve on will force the core to move down, shutting off the flow and closing the valve.

Solenoid Efficiency and Power Consumption

Solenoids are generally energy-efficient, but their power usage depends on several factors such as the number of wire coils, the thickness of the wire, and the electrical current applied.

Efficiency Factors:

- Coil Design: The number of turns in the coil and the wire gauge affect efficiency. More turns can increase magnetic field strength, but also increase resistance and heat generation.

- Core Material: High-permeability materials like iron or specialized alloys can improve magnetic field strength and efficiency.

- Duty Cycle: Continuous operation can lead to overheating and reduced efficiency. Some solenoids are designed to consume power only while actively engaged, while others may require continuous power to hold a position. For applications with intermittent use, selecting a solenoid designed for shorter duty cycles can improve performance and reduce energy consumption.

- Plunger Design: The shape and material of the plunger impact the solenoid's force output and efficiency. A well-designed plunger minimizes friction and maximizes the conversion of magnetic energy into mechanical work.

- Current Flow: Solenoids rely on electric current to generate a magnetic field. The more current applied, the stronger the magnetic field—and the more energy consumed. However, it’s essential to select a solenoid with the correct current rating for optimal efficiency and avoid overheating.

The Strength of a Solenoid

If you’ve ever used a pneumatic tool, you’ve used a small solenoid. Your compressor had pressurized air in it. You pressed the trigger of your nail gun because you wanted a puff of that compressed air to drive a nail in for you. When you did so, a solenoid valve opened up for a fraction of a second, allowing a dose of that pressurized air to shoot from the compressor to the gun and drive that nail.

Moving a valve as small as that one doesn’t take much power, but a solenoid in a larger tool-- perhaps managing more significant quantities of liquid or gas-- needs more. The power available from a solenoid comes from the number of coils in the wire and the current sent through it.

Governed by Ampere’s law, which is a mathematical equation that considers these elements to determine the strength of the electromagnetic field, the magnetic field equation allows for determining how many coils and how much current one needs to adequately power a solenoid valve.

Applications

Stronger or weaker solenoids find use depending on need. A large, powerful solenoid with many coils and a large electrical current is unnecessary for making your doorbell ring. A small solenoid can accomplish this.

But a solenoid valve on an oil derrick would need to be much more powerful. While all solenoids are electrical-- you cannot have an electromagnet without electricity-- the variety of jobs they do requires different types.

- Electrical. This term governs all solenoid valves, as electricity must be involved.

- Pneumatic. Pneumatic solenoid valves allow for the movement and suppression of gasses such as air, nitrogen, and carbon dioxide.

- Hydraulic. A valve that governs the motion of liquids, from water to bourbon to gasoline.

When you start looking for them, you will find that solenoids and solenoid valves are everywhere in modern life, and they make many tasks we do every day much more manageable.

Testing a Solenoid

Your solenoid valve may stop opening and closing from time to time, or the solenoid in your car may not start your car one day. Diagnosing these problems is key to fixing them, so there are few simple ways to do that.

The simplest way is with a compass. Your solenoid works with electromagnetism. If the solenoid is not working, it will not create a magnetic field.

Put a compass near the solenoid. Then turn on the solenoid. This will help you see if it is the problem or if there is another issue. If your compass needle jumps, the solenoid creates a magnetic field. If not, then your solenoid is not getting the electricity it needs.

In this case, you can further determine the issue with a multimeter. Before that, though, your first step is to check the connections. If your positive or negative terminals are disconnected or are in any way faulty, the solenoid cannot work even if it is in pristine condition. Even if the connections look good, you should use your multimeter to determine the solenoid’s continuity.

Once you’ve determined that the connections are good, switch your multimeter over to its resistance setting. If you get a reading over 0.3 ohms, the unit isn’t functioning as it should. It is not conducting enough electricity to work and needs replacing.

For more information on how to diagnose and fix a problem, see our solenoid valve troubleshooting resource.

Solenoid FAQs

How fast do solenoids operate?

Solenoids can operate very quickly, with response times often in the millisecond range. However, the exact speed depends on the specific design and application

Q: What is the difference between an electromagnet and a solenoid?

A: While both solenoids and electromagnets use electrical current to generate a magnetic field, their purposes differ. A solenoid converts electrical energy into mechanical motion, whereas an electromagnet's primary function is to generate a magnetic field for tasks like lifting or holding metallic objects.

How long do solenoids typically last?

The lifespan of a solenoid depends on its design, quality, and operating conditions. With proper maintenance and usage, solenoids can last for many years.

What causes solenoid failure?

Common causes include overheating, wear and tear on moving parts, electrical issues like short circuits and poor electrical connections, and environmental factors such as moisture or contaminants.

How can I test if my solenoid is working?

One simple way to test a solenoid is by using a multimeter to check for electrical continuity. If the solenoid doesn’t create a magnetic field or the multimeter shows no continuity, the solenoid may need to be replaced. You can also use a compass to see if it generates a magnetic field when energized.

What are the common applications of solenoids?

Solenoids are used in a wide range of applications, including automotive starters, door locks, industrial valves, medical devices, and consumer electronics.

What are the advantages of using solenoids?

Solenoids offer several advantages, including fast response times, high reliability, compact size, and simple operation.

Conclusion

Solenoids are found nearly everywhere in our modern world. We use them to start cars, operate dialysis machines, control dishwashers, even manipulate our speakers into producing music from an electrical signal. While our lives would be very different without them, solenoids are simple creations.

Requiring only wire, a magnetic core, and an electrical current, functioning solenoids can be fashioned in a middle school science class, but they help us accomplish hundreds of tasks, some of which would be impossible without them.

For being such a large part of our world, solenoids are simple mechanisms that require only a basic grasp of physics most of us learned in middle school. Understanding them is not difficult, and you don’t have to know any mathematical formulas to learn their secrets.

Still Have Questions

Need help choosing the right solenoid valve for your project? Explore our extensive collection of solenoid valves, or contact our valve experts for personalized advice. Our valve experts are available during regular office hours via phone or the chat function below.