Jul 15th 2024

How Solenoid Valves Optimize Modern HVAC Systems for Efficiency and Reliability

In the complex world of building climate control, the development of Heating, Ventilation, and Air Conditioning (HVAC) systems has revolutionized our ability to create ideal environments tailored to specific requirements. From cozy homes to bustling commercial spaces, and from critical healthcare settings to high-tech industrial complexes, HVAC systems consistently ensure comfort, safety, and efficiency.

However, at the heart of these sophisticated systems is an often-overlooked component: the solenoid valve. This electromechanical marvel plays a critical role in orchestrating the nuanced dance of heating, cooling, and ventilation. Dive into this comprehensive exploration of modern HVAC systems to learn about the indispensable role of solenoid valves, their various types, and the essential criteria for their selection in today's advanced HVAC technology.

About HVAC Systems

The term HVAC stands for Heating, Ventilation, and Air Conditioning. HVAC systems are often critical and integral to the creation of a controlled environment within various types of buildings, including residential homes, commercial structures like offices and malls, and industrial facilities such as factories. As opposed to traditional ventilating or cooling systems, which perform a singular unique task — either heating, ventilating, or cooling, HVAC systems are more versatile. A single integrated HVAC system can serve multiple needs for an industrial/commercial establishment:

- Heating (H): Enables controlled temperatures, critical for hospitals, chemical, and manufacturing industries.

- Ventilation (V): Ensures the circulation of fresh air and removal of pollutants, and vent smoke and hazardous emissions from DG (Diesel Generator) sets.

- Air Conditioning (AC): Cools the air, controls humidity, and ensures precise temperature control settings for the optimal performance of servers and food storage facilities.

Amongst the three segments of an HVAC-R (excluding R-Refrigeration), the Air Conditioning (AC) segment dominates the global market for HVAC systems and accounts for the largest revenue share of 54.8% in 2022 ( source), and just the residential Cooling segment was globally valued more than USD 50.0 billion (on 2021).

Application areas of HVAC - Where Are HVACs Used?

Across sectors, HVAC systems are becoming increasingly popular, with forecasts estimating the HVAC demand to grow at a CAGR exceeding 6.8% between 2023 to 2030 ( source), thanks to their high efficiency, integrated automation, and intelligent control features.

Initially prevalent in industrial settings, HVAC systems have now gained substantial traction in the residential sector. In 2022, residential applications accounted for a dominant 39.9% of the total HVAC market revenue ( source). This increased demand can be attributed to the growing population in emerging markets and market maturity in developed markets. The other application sectors of HVAC include:

- Residential Buildings: Homes, apartments, and condominiums.

- Commercial Buildings: Offices, malls, restaurants, hotels, and gyms.

- Industrial Facilities: Factories, warehouses, and manufacturing plants.

- Healthcare: Hospitals, laboratories, and clinics.

- Transport: In trains, buses, and airplanes to maintain a controlled atmosphere.

State of HVAC Adoption — Modern Vs. Traditional HVAC systems:

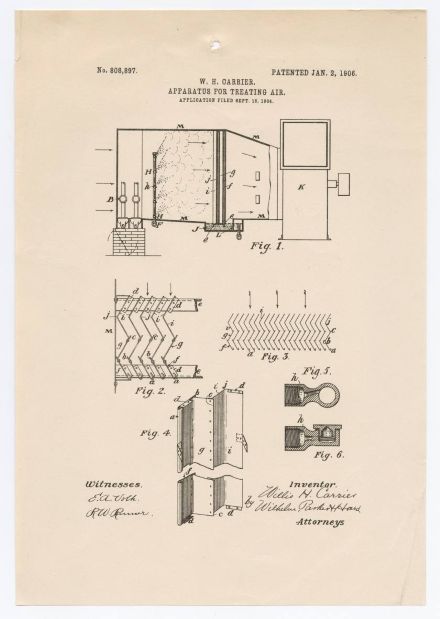

The origins of HVAC systems date back to the 19th century primarily to control indoor environments. In 1902, Willis Carrier, an American engineer, introduced the first modern air conditioning system in Brooklyn, New York, and the system regulated both temperature and humidity, marking a significant advancement.

From then on, the HVAC technology evolved from providing basic functions of heating, ventilation, and air conditioning. While in the initial years, the goal was to offer comfort and ensure proper ventilation, energy efficiency and environmental impact were not significant considerations. Hence, these systems used refrigerants like R-22 (Freon), which, though effective, had a significant ecological impact.

By the late 20th and early 21st century, there was growing awareness about the environmental impacts of HVAC systems and the need for energy-efficient designs. Today, HVAC systems are a fusion of efficiency, smart technology, and environmental responsibility. They not only focus on heating and cooling but also on indoor air quality, integrating air purification systems, and ensuring energy efficiency.

Image Explanation:

The attached image is a historic patent design for an air treatment apparatus by Willis H. Carrier, dated January 2, 1906. This design marks one of the earliest modern air conditioning systems, illustrating the foundational principles of temperature and humidity control. Carrier's invention laid the groundwork for contemporary HVAC technology by introducing mechanisms for regulating air quality and comfort levels within buildings. The design includes detailed diagrams showcasing various components and their interactions, highlighting Carrier's innovative approach to environmental control. Image source -

National Archives' AOTUS Blog

| Criteria | Traditional HVAC System | Modern HVAC System |

|---|---|---|

| Energy Rating and Efficiency | Lower efficiency; often single-stage systems with basic operation. | High efficiency; multi-stage or variable-speed compressors. |

| Control Systems | Manual thermostats; limited zoning capabilities. | Smart thermostats; advanced zoning with individual room control. |

| Integration | Standalone systems without external integrations. | Can be integrated with smart homes, renewable energy sources, and building management systems. |

| Maintenance | Requires more frequent maintenance due to lack of system diagnostics. | Self-diagnostic tools; predictive maintenance capabilities. |

| Refrigeration (HVAC-R) | Limited or no integration with refrigeration systems. | Integrated refrigeration options for broader applications. |

| Environmental Impact | Often uses refrigerants with higher global warming potential (GWP). | Uses environmentally friendly refrigerants with lower GWP. |

| Design Flexibility | Fixed design; challenging to upgrade or modify. | Modular and scalable; can be easily modified or expanded. |

| Lifespan | Shorter lifespan due to wear and tear of traditional components. | Longer lifespan (about 20-25 years) owing to improved materials and engineering. |

| Cost of Operation | Often higher due to energy inefficiencies and frequent maintenance. | Reduced operational costs due to energy efficiency and fewer maintenance needs. |

Case Study: Improvements in Energy Efficiency in a Five-Star Hotel's HVAC System

Transition from traditional to modern HVAC systems underscores substantial benefits. A case in point — a five-star hotel in China modernized its HVAC system, focusing on enhancing the main chiller's efficiency, balancing chilled water hydraulics, and introducing a free-cooling system. These strategic changes led to a remarkable energy saving of 359,000 kWh/year , with improved performance of building systems and indoor thermal comfort, and hence validating the effectiveness of adopting modern HVAC systems.

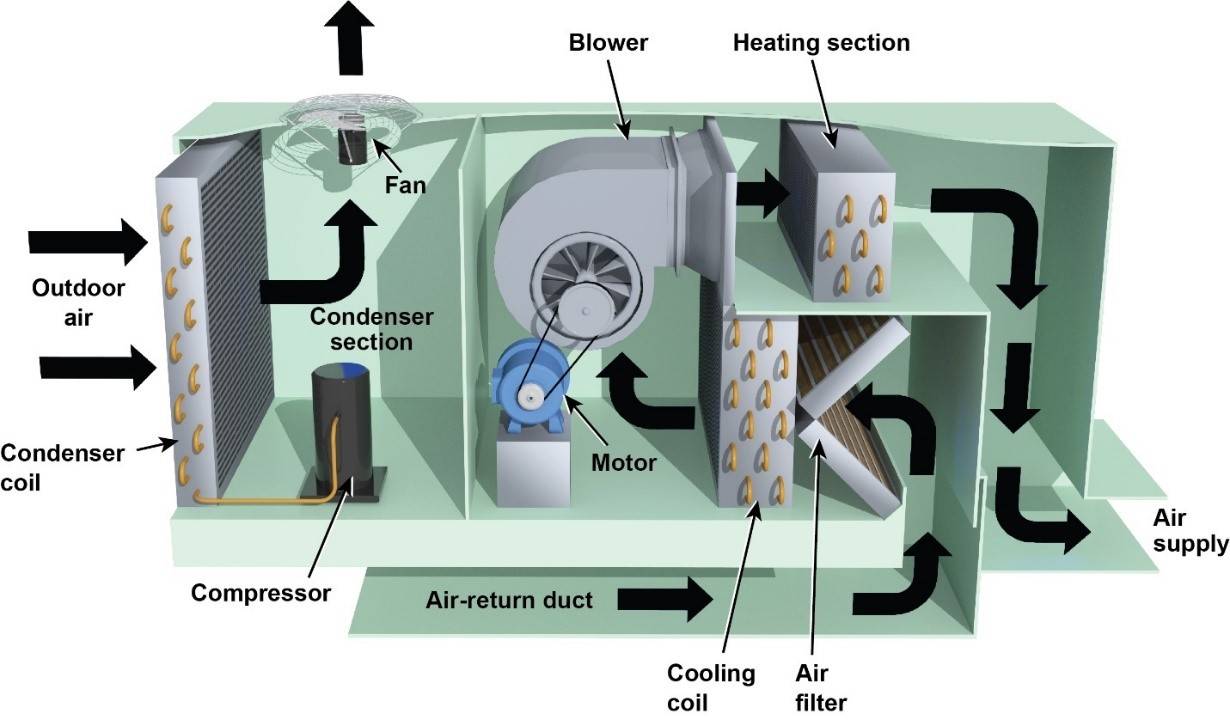

Operational Stages — Understanding the Critical Process and Components of a Modern HVAC Systems

Image Source: "Operational Stages and Components of a Modern HVAC System," retrieved from Pacific Northwest National Laboratory's best practices for unitary HVAC equipment. Available at: PNNL - Best Practices for Unitary HVAC Equipment.

A modern HVAC system is composed of several critical components and processes that work together to provide heating, ventilation, and air conditioning. To simplify, the operational stages of a modern HVAC system (Cooling/Refrigeration) can be broken down into the following steps:

- Air Intake: Fresh air is drawn into the system through an intake vent, which is typically located on the roof or exterior wall of a building.

- Air Filtration: The air is then passed through a series of filters to remove pollutants and particulates such as pollen or fine dirt.

- Heating or Cooling: Depending on the desired temperature, the air is either heated or cooled using a heat exchanger or evaporator coil.

- Humidity Control: The humidity of the air is controlled using a humidifier or dehumidifier.

- Air Distribution: The conditioned air is then distributed throughout the building using a network of ducts and vents.

The critical components of a modern HVAC system include the compressor, condenser, evaporator, expansion valve, and fan. These components work together to control the flow of refrigerant and regulate the temperature and humidity of the indoor environment. However, it is necessary to understand each process of HVAC in brief to determine how solenoid valves are crucial for HVAC operations. The following table debriefs and compares each stage of the HVAC System:

| Operational Stages | Traditional HVAC System | Modern HVAC System |

|---|---|---|

| Stage - 1: Compression | Standard compressors that operate at a fixed speed. | Variable-speed compressors which adjust their speed based on demand. |

| Stage - 2: Condensation | Basic condenser coils, often with limited control over efficiency. | Enhanced coil designs with improved materials for better heat transfer and efficiency. |

| Stage - 3: Expansion | Fixed orifice for refrigerant flow, which provides less precision. | Thermostatic expansion valves (TXVs) or electronic expansion valves (EXVs) that adjust based on the system's needs. |

| Stage - 4: Evaporation | Standard evaporator coils may have issues with frost accumulation. | Enhanced evaporator coil designs, often with features to reduce frost buildup and improve efficiency. |

Modern HVAC systems also often include advanced features such as integrating with IoT Sensors, programmable thermostats, zoning systems, and smart remote controls to improve energy efficiency and user comfort.

Image - https://www.pnnl.gov/projects/om-best-practices/unitary-hvac-equipment

Role of Solenoid Valves in HVAC

Solenoid valves, as

integral components of modern HVAC systems, address a range of challenges that

traditional systems grapple with. Their inclusion underscores their paramount

importance in ensuring the efficiency and reliability of advanced HVAC setups:

Solenoid valves, as

integral components of modern HVAC systems, address a range of challenges that

traditional systems grapple with. Their inclusion underscores their paramount

importance in ensuring the efficiency and reliability of advanced HVAC setups:

#1. Precision and Control of Fluid Flow:

One of the most pressing challenges in HVAC systems is achieving exact control over airflow and refrigerant flow. Flow control is traditionally done with manual valves or relay-controlled systems; however, Solenoid valves have rapid response times, with some models capable of between 10 and 1000 milliseconds. This ensures precise control over airflow and refrigerant flow, resulting in optimal system performance as designed.

#2. Low Energy Efficiency:

HVAC systems are often energy-intensive by design, especially for higher volume flow (high CFM). Hence, optimizing the performance of valves and other critical components will contribute to the overall system efficiency. Recent advancements in coil technologies have boosted solenoid valve efficiency by 80% ( source), contributing to reduced energy consumption, and quicker response times, hence improving the overall efficiency of the system.

#3. Complex System Integration and Remote-Control Capabilities:

As modern HVAC systems become more integrated with smart building technologies, there's a need for components that can be controlled electronically. Solenoid valves, being electrically operated through IoT Gateways, seamlessly fit into these advanced integrated systems. Coupled with Flow sensors, HVACs can be monitored and controlled through Cloud Dashboards .

#4. Absence of Auto-Shut Off and Safety Measures:

HVAC malfunctions can be dangerous, leading to hazards like gas leaks or system blowouts. Solenoid valves can be programmed to automatically shut off the flow of gas or refrigerant , preventing further damage or harm in emergencies. Most valves are designed to be fail-safe, implying that the SVs will automatically close in the event of a power failure or other emergency, providing an essential safety layer.

#5. Wear and Tear of Mechanical Valves:

Traditional mechanical valves can often result in inefficiencies due to wear and tear. Solenoid valves use an electromagnetic coil to control fluid flow and hence minimize the number of moving components (except for the plunger), resulting in less friction and wear. Most SVs are rated for millions of cycles, ensuring long-term reliability with fewer maintenance issues.

#6. Zoning Capabilities:

For advanced HVAC systems offering zoning solutions, directing heating, or cooling to specific zones as needed can be challenging. Zone Valves or Motorized Solenoid valves can assist in this precise zoning, ensuring individual areas receive the requisite airflow.

#7. Eliminating Manual Adjustments:

Traditional systems may require manual valve adjustments, which can be both labor-intensive and less accurate. Solenoid valves, with their automated control, eliminate this challenge. To further ensure smooth operation and protect your solenoid valves, consider integrating our Y strainers and check valves.

In essence, solenoid valves emerge as a critical solution to many of the challenges inherent in HVAC systems. Their role in ensuring safety, enhancing performance, and optimizing energy efficiency emphasizes that Solenoid Valves are indispensable in any modern HVAC design.

Selecting Solenoid Valves for HVAC Systems

Solenoid valves are electromechanical devices that regulate the flow of a fluid or gas. Their application in HVAC systems is pivotal, and understanding their types along with selection criteria is vital for ensuring optimal system performance.

Explore our range of high-quality steam solenoid valves designed for optimal performance in HVAC systems.

To simplify Solenoid Valve selection, let us group HVAC into two segments - Cooling and Heating, since the process and the components change for these two. We will explore Solenoid valves and their selection criteria for these two segments — heating and cooling (i.e., air conditioning and refrigeration) applications:

A. Solenoid Valves for ‘Cooling’ HVAC Segment - Types & Selection

Solenoid valves are integral components in refrigeration and air conditioning (AC) systems, chiefly regulating refrigerant flow, which is pivotal for optimal system performance. When choosing a solenoid valve for such applications, the following factors must be considered:

- Material Compatibility with Refrigerant: It is essential that the solenoid valve materials be suited for the refrigerants in use. For instance, stainless steel is often selected for the valve body when dealing with common refrigerants like R22 (freon), R404A, R410A, and R290 or with lower-GWP (Global Warming Potential) refrigerants, including R290 propane. The seals, often made of NBR, should also be resistant to these refrigerants.

- Operation Type - Direct, Semi-Direct, or Servo: Solenoid valves come in various operation types, including direct-operated, semi-direct-operated, and servo-operated. Direct-operated valves are known for their simplicity in design. Semi-direct-operated and servo-operated solenoid valves, on the other hand, are often preferred for larger AC and refrigeration systems. When using servo-operated valves, it's essential to pay attention to the differential pressure. Ensuring that the differential pressure remains above the valve's specified minimum during partial loads is crucial.

- Size, Thread, & Positioning of the Solenoid Valve: The valve size can be selected to ensure minimum pressure drop across the line. Ideally, a minimum of 1 psi pressure drop ensures efficient operations. However, the Thread size of SV is also important to ensure minimal pressure drop. Also, these valves should be strategically placed in the liquid line, proximate to the expansion valve. Such a positioning minimizes the potential for water hammer effects, which can be detrimental to the system.

- Operational Status - Normally Closed or Open: Solenoid valves predominantly come in two configurations: normally closed (where the valve remains shut when not energized) and normally open (where the valve stays open when not energized). For valves situated in the liquid line, the 'normally closed' variant is preferred. This choice ensures that, in the event of a system halt or power disruption, the valve stays closed, preventing refrigerant migration (a scenario where refrigerant inadvertently moves to the compressor when off). On the flip side, 'normally open' valves are ideal if the valve needs to be closed only intermittently.

- Adherence to Safety Norms: Given the high stakes in refrigeration and AC systems, solenoid valves should be compliant with several safety and quality standards, such as ATEX, LVD, and PED. Familiarity with CE certification and other relevant valve regulations ensures that the components in use meet the prescribed safety criteria.

B. Solenoid Valves for ‘Heating’ HVAC Segment - Types & Selection

Selecting the right Solenoid valve for heating applications is critical to achieving energy efficiency and safety. Their primary function is to control the fuel flow to the furnace. As the temperature decreases below a set point, the valve activates, enabling gas to reach the burner. Once the set temperature is achieved, the valve restricts the gas supply.

The following guidelines can be considered while selecting the right solenoid valve for your HVAC heating application:

- Material Selection: Given that furnaces utilize combustible fuels like natural gas or propane, it's imperative to choose materials that can withstand these fuels without degradation. Suitable materials for the valve's body include brass, aluminum, cast iron, or stainless steel. For seals, nitrile rubber is a favored choice due to its resilience.

- Operational Parameters (Pressure Difference & Temperature): Solenoid valves must be designed to manage a broad spectrum of pressures, often 30 psi or even higher. If the valve is to function under extreme temperatures, it's crucial to choose a model rated for such conditions. For instance, applications requiring operation at very low temperatures (around -40°C) necessitate specialized elastomers to ensure no leaks occur.

- Safety Measures: Safety is paramount when working with combustible media. It's essential to choose solenoid valves that come with explosion-proof certifications. These certifications ensure that the valve's coil or housing is designed to prevent and contain any potential explosions. Look for valves endorsed by recognized standards such as NEMA (National Electrical Equipment Manufacturers Association, USA), ATEX (ATmosphères EXplosibles, EU), or IEC Ex (International Electrotechnical Commission Explosive, globally).

- Ingress Protection (IP) Ratings: The environment in which the solenoid valve operates may expose it to elements like dust, moisture, or even potential physical damage. It's advisable to select valves with suitable IP (Ingress Protection) ratings that certify their resilience against such factors. To further understand the intricacies of solenoid valves designed specifically for fuels, delve into our comprehensive article on fuel, oil, gas, & propane solenoid valves .

Other Parameters to Consider while selecting Solenoid Valves for HVAC Segment applications:

- Temperature Tolerance: Given the wide range of operating temperatures that HVAC systems operate under, solenoid valves must be designed to function efficiently under extreme low-temperature conditions.

- Maintenance and Durability: Valves that are easy to dismantle, inspect, and service can reduce downtime, ensuring that the HVAC system remains operational with minimal disruptions.

- Energy Efficiency: Modern solenoid valves are often designed with energy efficiency in mind. Their coils are optimized to require less power, thereby conserving energy, and reducing operational costs. For businesses, particularly large establishments, these savings can be substantial over time.

- Coil Encapsulation: This practical feature ensures that the solenoid coil is protected from external factors like moisture, dust, or chemical exposure. Especially in environments like commercial kitchens or chemical storage areas, where there's potential exposure to various substances, encapsulated coils ensure consistent performance.

- Manual Override Feature: Some advanced solenoid valves come with a manual override function, allowing technicians or operators to manually open or close the valve in case of an electrical failure. This feature can be invaluable during emergencies or maintenance activities, ensuring that the system can be controlled even when the electric function is compromised.

The correct choice and application of solenoid valves in HVAC units can significantly influence the efficiency, safety, and longevity of the entire system.

Incorporating these practical aspects into the selection process for solenoid valves in HVAC ensures that the chosen component not only meets the technical specifications but also aligns with real-world operational challenges and requirements.

Advantages of Solenoid Valves in Modern HVAC Systems:

As seen in the earlier

sections, Solenoid valves are crucial and yield several benefits with modern

HVAC systems, these include:

As seen in the earlier

sections, Solenoid valves are crucial and yield several benefits with modern

HVAC systems, these include:

- Precise Temperature Control: Solenoid valves enable accurate modulation of refrigerants and other fluids, ensuring that HVAC systems maintain desired temperatures consistently. This precision enhances occupant comfort and energy efficiency.

- Quick Response Time: Their rapid actuation capability allows HVAC systems to promptly adjust to temperature fluctuations, optimizing performance and reducing energy consumption.

- Reduced Maintenance: Built for durability and efficient performance, solenoid valves require minimal maintenance, which translates to decreased downtime and operational costs for HVAC systems.

- Energy Efficiency: By regulating the flow of refrigerants effectively and operating only, when necessary, solenoid valves can significantly reduce the energy consumption of an HVAC system, leading to lower utility bills.

- Seamless Integration: Modern solenoid valves are designed to integrate effortlessly with advanced HVAC system controls, facilitating real-time monitoring, feedback, and automation for optimal system performance.

Calibration and Performance Maintenance of Solenoid Valves in HVAC Systems

Calibration and performance maintenance are essential aspects of ensuring the long-term and efficient operation of solenoid valves in HVAC systems. Let us explore the correct maintenance and calibration method for solenoid valves:

Calibration of HVAC Solenoid Valves:

Calibration is crucial to ensure that the solenoid valve operates correctly, especially regarding its response to control signals. Calibration ensures that the valve opens and closes at the right times and to the correct extent. This is particularly significant in applications where precise control is essential, like in temperature-sensitive environments.

- Verification of Set Points: Regular checks are carried out to verify that the solenoid valve activates and deactivates at the correct set points.

- Flow Rate Checks: For HVAC systems where the solenoid valve controls flow rates , calibration checks can confirm that the right volume of refrigerant or fluid is flowing when the valve is open.

Performance Maintenance of HVAC Solenoid Valves:

Maintaining the performance of a solenoid valve encompasses various activities aimed at ensuring the valve's longevity and efficiency:

- Visual Inspections: Regular visual checks can identify apparent issues like corrosion, leaks, or physical damage to the solenoid valve.

- Cleaning: Over time, debris can accumulate within the valve, especially if the HVAC system deals with large volumes of air from the outside. Regular cleaning can ensure that this debris doesn't impede valve function.

- Seal and Gasket Checks: The seals and gaskets in solenoid valves can wear out or degrade over time. Regular inspections can identify when these parts need replacement.

- Electrical Tests: Given that solenoid valves operate electrically, tests can be done on the coil and the connections to ensure there's no degradation in electrical performance.

- Functional Tests: Periodic tests can be carried out to ensure the valve actuates correctly in response to control signals. This can identify issues with sluggish response times or incomplete closing/opening.

Following dedicated calibration and performance maintenance practices are fundamental to ensure optimal operation of solenoid valves in HVAC systems. Properly maintained valves contribute to the efficiency, safety, and reliability of the overall HVAC system.

Read More: Solenoid Valves: Failure, Operational & Maintenance Guidelines for Reliable Performance

Conclusion:

Modern HVAC systems have undergone significant transformations in recent years, incorporating advancements that substantially improve efficiency. State-of-the-art systems now adopt eco-friendly refrigerants, smart controls, and energy-efficient designs that reduce operational costs and environmental footprints.

However, a deep dive into the workings of modern HVACs reveals a myriad of critical processes and components, central among which is the solenoid valve. Solenoid valves, often deemed indispensable, manage the precise control of refrigerants and other fluids within the system. These valves, pivotal in overcoming numerous industry challenges, ensure system performance, safety, and efficiency.

Though there is a rich array of solenoid valve types tailored for HVAC applications, ensuring compatibility with specific HVAC requirements is essential.