May 29th 2024

What is the Purpose of a Check Valve?

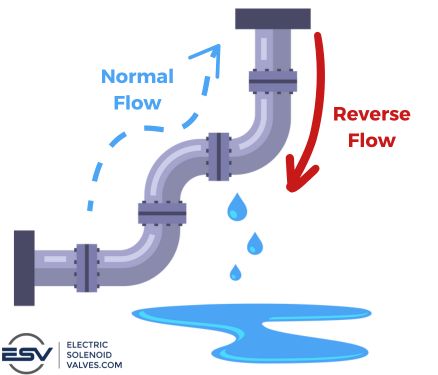

The Problem of Backflow

When dealing with different fluid control systems, backflow is a serious issue that can lead to significant problems. When fluids or other media flow in the wrong direction, it can damage equipment, contaminate clean fluids, reduce work efficiency, and create serious safety hazards. For example, in water treatment facilities, backflow can cause serious health risks by contaminating drinking water. In HVAC systems, backflow can cause corrosion by mixing air and water. In your own home, backflow can be the reason your pipes are banging when you turn on the water.

Luckily, there is a simple, and inexpensive, solution to preventing problems caused by backflow…

What is a Check Valve?

Check valves are crucial components in fluid systems to prevent backflow. They act as a one-way gate that only allows media to flow in the desired direction, while blocking any reverse flow.

How Check Valves Work

The basic operating principle of a check valve is simple, yet effective. As fluid flows in the intended direction, the valve opens and allows it to pass through. When the direction of the media reverses, the pressure causes the valve to automatically close, creating a seal to prevent backflow.

How Check Valves Solve the Backflow Problem

There are different types of check valves. The two most common types are vertical/spring check valves and swing check valves. Both types are highly effective in preventing backflow and keeping media flowing in the proper direction.

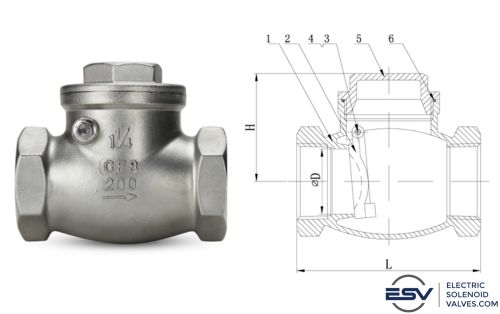

A swing check valve contains a hinged disc (or flapper) in the valve body. With little pressure from the media flowing against it, the disc swings open to allow it to pass through in the intended direction. Once the media flows in the opposite direction, the pressure presses the disc back to create a seal.

Spring (in-line) check valves use a spring mechanism to close the valve when flow stops. Spring-loaded check valves are powered by flow and differential pressure, like the swing check valves, but with added assistance from spring pressure. The spring holds the valve disc closed until forward (cracking) pressure overcomes the spring force, which then allows flow. When the pressure drops, the spring reseals the valve. The operating function of this type of valves allows them to be installed in any orientation.

Both types of check valves are incredibly reliable and require minimal maintenance, making them a cost-effective solution for backflow prevention. Their automatic operation does not require oversight, and can save companies and homes a fortune on the damage they prevent.

The Purpose of a Check Valve

Preventing Backflow

The primary purpose of a check valve is to prevent backflow. Doing so protects equipment, prevents contamination, helps maintain system pressure, and prevents water hammer.

Protecting Equipment

Backflow can be devastating to equipment within the system such as pumps, compressors, and other mechanical components. When fluids flow in the wrong direction, they can cause excessive wear, damage seals, or even lead to failures within the system. Check valves are a safeguard that protects this equipment from the harmful effects of backflow.

Preventing Contamination

In systems where different fluids are involved, backflow can inadvertently lead to the mixing of these fluids. This kind of contamination can be a nightmare for industries like food processing or pharmaceuticals where fluid purity is required. Check valves are used to prevent treated water, chemicals, or other substances from flowing backwards and mixing with untreated or incompatible fluids.

Maintaining System Pressure

Check valves also help maintain system pressure by preventing the loss of fluid due to backflow. This is an important feature for applications where consistent pressure is essential, such as HVAC and irrigation systems

Preventing Water Hammer

Check valves are also an important tool used to help mitigate water hammer. Water hammer results from a water pressure surge in your pipes, often occurring after an abrupt direction change, burst from a previously clogged pipe, or a sudden valve shutdown from within the plumbing system. Installed check valves allow a more controlled deceleration of the fluid flow when a valve closes, dissipating the kinetic energy of the moving liquid. This energy dissipation helps to mitigate the effects of water hammer.

Common Applications of Check Valves

Check valves are widely used in industrial settings as well as residential. Here are some common applications where check valves play a critical role:

Water and Wastewater Systems

In residential plumbing, check valves prevent contaminated water from flowing back into the clean water supply, which could otherwise introduce harmful bacteria, chemicals, or contaminants into drinking water. They're also used in irrigation systems to keep water flowing to crops and lawns without backflow into the main supply. In wastewater treatment plants, check valves prevent sewage from backing up into homes and businesses, which is a big deal for obvious reasons.

Industrial Processes

Manufacturing, chemical processing, and power generation industries rely heavily on check valves. They protect pumps, compressors, and other equipment from backflow, saving companies from expensive repairs and downtime. Check valves also play a vital role in maintaining pressure and preventing contamination in these complex systems.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, check valves prevent the reverse flow of air or water. Heated and cooled air can then be delivered to the intended spaces as the water circulates properly through boilers and chillers. This prevents damage to components and helps optimize the system to maintain the desired temperature and pressure levels without disruptions.

Other Applications

Check valves find use in countless other applications, including:

- Oil and Gas Pipelines: Preventing backflow and maintaining pressure in vast pipeline networks.

- Fire Suppression Systems: Ensuring the unidirectional flow of water or fire suppressants.

- Medical Equipment: Safeguarding patients and maintaining the sterility of medical devices.

Prevent Backflow: Expert Help & Fast Shipping

Need a check valve fast? We have thousands of check valves in stock, ready to ship, and can get your order out the door by the next business day, with fast shipping options available. Have questions or need help selecting the right check valve? Our valve experts at ElectricSolenoidValves.com are here to help via phone, email, or chat during business hours. Leave us a message after hours, and we'll get back to you promptly the next business day.