Sep 9th 2021

AC vs. DC Current Solenoid Valves

Solenoid valves incorporate the use of coils and metal cores to regulate the flow of liquids and gases. They are electrically controlled devices that require either AC or DC energy to power the coils, which then convert the electrical energy into linear motion.

Understanding the differences between AC (Alternating Current) and DC (Direct Current) solenoid valves is essential for selecting the right valve for your specific needs. In this article, we'll delve into how solenoid valves work, explore the key differences between AC and DC solenoids, and guide you in choosing the most suitable option for your application.

How Solenoids Work

To better understand the differences between AC and DC solenoid valves, let’s quickly go over how a solenoid works within the valves.

At the core of the valve is a solenoid, and it consists of two main parts: a helical coil made of copper and a movable ferromagnetic core. The core is also called the plunger or armature, and the coil wraps around it to form a cylinder.

In the resting position, the plunger extends outside the coil, and spring tension keeps it out. When you power the solenoid, electricity flows through the coil to create an electromagnet. Regardless of the current polarity, the magnet attracts the armature to the center of the coil. When this happens, it opens a port in the valve to allow media to pass through.

Switching off the power halts the electromagnet, which releases the plunger. The spring takes over and pushes it back to its resting position, which closes the valve port.

For the system to work, the magnetic force generated by the coil must be greater than the spring’s force, the friction of moving the armature from the port, and the media’s hydraulic pressure combined.

Switching power on/off to the coil causes the conversion of electrical energy into mechanical/linear energy by raising or lowering the plunger.

While there are many mechanical variations of the device used in car starters, latches, solenoid valves, switches, etc., the basic design (electromagnet) is the same.

Differences Between AC and DC Solenoid

While both AC and DC solenoid valves perform the same basic function, the type of electrical current they use introduces differences in their operation, performance, and suitability for certain applications.

DC Solenoid Valve Working Principle

For the DC valves, the working principle is straightforward. When the coil gets energized, it creates a magnetic force that pulls the armature to open the valve port. When you cut off the power supply, the coil is de-energized, and the spring pushes the armature back to close the valve.

The direct current in DC solenoid valves provides a continuous magnetic pull that creates a smooth and quiet operation without vibrations.

AC Solenoid Valve Working Principle

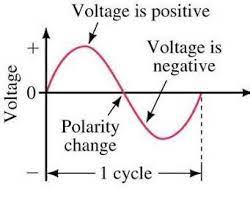

AC solenoids operate a bit differently. AC alternates, which means the current changes polarity several times each second, forming a sinusoidal wave.

*Image source - US Naval Academy

If you plot it on a chart, there are two periods when the current will be at zero per cycle so that the coil will be energized and de-energized continuously. Therefore, the magnetization will be on/off, and the spring will push the plunger out when it is off.

The result is intense vibrations, which create a lot of stress and overheat the coil to the point of burning out.

How AC Solenoids Solve the Issue of Vibrations

We obviously don’t want a coil that will burn out after one use. This vibrarion issue has been addressed with a tweak to the design.

AC solenoid valves incorporate the use of shading rings fixed right above/around the plunger to mitigate vibrations. The shading ring is a small copper ring that stores some magnetic energy to help overcome the spring’s force when the electromagnetic field goes towards zero.

Compared to the sinusoidal wave created by the coil, the shading releases its stored magnetic field energy 90 degrees out of phase. Therefore as the coil’s field dips towards zero, the ring’s field peaks to fill the void.

If you plot the magnetic fields of the two together, it will never hit zero. So long as the coil has energy, this field will be enough to overcome the spring force, and this will eliminate the occurrence of vibrations.

Design Improvements?

The problem with the shading ring is that it may be ineffective if the area around the plunger fills with dirt and debris. One of the improvements would be to use a full-wave rectifier to convert AC to DC because it harnesses both cycles of the AC.

However, this effectively means the solenoid valve must be a DC type because, whether the rectifier circuitry is internal or external, it converts the energy before it gets to the coils. Thus, you might not get the full benefits of an AC solenoid.

Differences in Performance

Apart from the structural/design differences between the two types of solenoids, they have several performance variations in the following areas.

Power Requirements

AC Solenoids: Consume high power initially for quick activation but require less power to remain activated.

DC Solenoids: Have a consistent power draw, which can lead to higher overall energy consumption.

AC solenoids have an edge over their DC counterparts when it comes to power requirements. At the start, they consume high levels of energy to create strong peak currents in the coils to open the valve.

While it may seem like a disadvantage, this is necessary because the initial magnetic force on the plunger must be high enough to overcome hydraulic pressure from the media, friction, and spring tension.

After the valve is open, the current (and magnetic force) required to keep the armature in position is relatively low. AC solenoids behave exactly this way because the current drops after the valves open. Therefore, they deliver sufficient opening force, then use little energy afterward, which helps to save on power consumption.

The case is very different for a DC solenoid valve because their power consumption rises slowly from the start, resulting in a slow valve opening. After this, the devices consume a constant amount of current, which is more than the amount required to keep the valve ports open. Therefore, DC valves waste vast amounts of energy as compared to the AC type.

However, their design can be improved using external circuits (such as having a capacitor and resistor in parallel). In such a case, charging the capacitor via the coil spikes the current, which provides enough power to open the valve quickly. On the other hand, the resistor limits the current that passes through to the coil once the capacitor is full.

That said, the setup still wastes energy because instead of ending up in the coil as excess, it ends up as heat on the resistor.

Noise and Vibrations

AC Solenoids: Consume high power initially for quick activation but require less power to remain activated.

DC Solenoids: Have a consistent power draw, which can lead to higher overall energy consumption.

AC solenoids have some drawbacks too, and one of them is in the production of noise and vibrations. Even though their design includes shading rings, there is the risk of vibrations in case this component fails. If this happens, the solenoid will produce a buzzing noise, and it will damage the unit.

However, with the DC type, there is no risk of buzzing because the current does not change polarity.

Eddy Currents

Another major drawback of AC solenoids is that they generate eddy currents and magnetic hysteresis losses due to the induced EMF in the plunger. The two cause power losses, which reduces the efficiency of this solenoid. However, by changing the armature material from iron to silicon steel sheet, the losses are reduced, so this is a crucial design improvement.

DC solenoids do not produce eddy currents because the electricity always flows in one direction.

Operating Time

AC Solenoids: Actuation speed can vary with frequency and may affect heat buildup.

DC Solenoids: Provide consistent operating times regardless of frequency changes.

With AC, the operating time is not constant because it varies with the operation frequency, and it also affects the coil’s heat buildup.

The case is different with DC as the operating time is constant. Regardless of the frequency, it will remain the same because this current travels in one direction.

Service Lifetime

The service life of both solenoid types depends on the wear and tear (friction) between the plunger and the valve pipe/guide. AC solenoids might experience faster wear if they begin buzzing from issues with their shading rings.

Excitation Current

In a DC unit, the excitation current depends on the coil’s internal resistance and voltage, but it is constant regardless of the stroke. When energized, the coil pulls the plunger to open the valve, reducing the size of the air gap progressively. At the same time, it minimizes the magnetic resistance.

As per Ohm’s law, magnetic flux is inversely proportional to the magnetic resistance if the field current is invariable. Therefore, as the plunger gets pulled in, the magnetic flux increases, raising the coil’s attractive force. Also, it means the force of the magnetic flux depends on the plunger position.

However, with AC solenoids, the excitation current varies depending on the stroke, and there is a big difference between the pre and post-armature closing processes. When starting, the current spike in these solenoids can be up to 15 times the excitation current.

Here, the AC voltage and frequency determine the solenoid’s magnetic flux while the magnetic resistance changes before & after the closing processes because the air gap also changes.

Using AC Solenoids with DC and Vice Versa

Even though the solenoids differ due to the type of current they use, it is possible to use DC or AC for coils rated for AC and DC, respectively. However, there are some restrictions.

For instance, when using DC in an AC solenoid, you must limit the voltage and current to keep the coil from burning out. Coils in AC solenoids add up their inductive reactance with electrical resistivity, which means the impedance is much higher than in DC-rated coils. As such, the solenoid might burn out quickly if you do not limit voltage and current.

Say the AC coil has a rating of 36V; if you power it using 36V DC, there is a high possibility of burning the solenoid because the direct current at this voltage is higher than the alternating current at the same voltage.

That said, there is no formula for determining the recommended DC voltage for an AC coil, so one of the solutions is to use a current limiting resistor. Though it may increase power losses, this device will ensure the current is lower than the coil’s AC rating. You can also reduce the supply voltage instead.

On the other hand, powering a DC-rated coil using AC runs the risk of creating vibrations and buzzing because such solenoids do not have shading rings. Of course, this setup will damage the solenoid because the vibrations will overheat the coil while the plunger will experience intense wear and tear.

The only solution to this problem is to convert the AC to DC using a full-wave rectifier and a capacitive filter. However, the current from this external circuit will be quite low and will create a weak electromagnet. As such, the solenoid might not be able to open the valve.

You can solve this by raising the voltage of the AC so that more current gets converted into DC.

However, in the end it is always better to have a professional electrician work with you if you’re not familiar with adjusting currents. You can get a converter or, often, it is as easy as switching out a coil to the correct voltage and current. If you’re not sure, we would recommend giving a call to your local electrician or reaching out directly to your manufacturer.

Choosing the Right Solenoid Valve

Selecting between an AC and DC solenoid valve depends on various factors related to your application's requirements.

Consider AC Solenoid Valves If:

- Rapid Actuation is Critical: Applications requiring quick opening and closing of valves benefit from the strong initial force of AC solenoids.

- Energy Efficiency is a Priority: Reduced power consumption after activation can lead to energy savings.

- AC Power Supply is Available: Utilizes existing AC infrastructure without the need for conversion.

Consider DC Solenoid Valves If:

- Quiet Operation is Necessary: Ideal for environments where noise reduction is important.

- Steady Force is Required: Provides consistent magnetic pull, beneficial for precise control.

- DC Power Supply is Available: Suitable for systems powered by batteries or renewable energy sources like solar panels.

Which One Is Better?

As you can see, each solenoid type has its advantages and disadvantages, so which is the best one. The answer to this depends on your intended use. Generally, DC solenoids are better because they do not run the risk of buzzing and overheating.

However, they are not as fast, so if the application requires a rapid valve opening response, it is better to use an AC solenoid.

AC vs DC Solenoid Valve Comparison Table

| Feature | AC Solenoid Valves | DC Solenoid Valves |

|---|---|---|

| Power Requirements | High initial surge, lower holding power | Consistent power draw, higher total energy use |

| Noise and Vibration | Can produce vibrations and buzzing; requires shading rings | Quiet, with steady pull force |

| Energy Efficiency | More efficient after activation due to low holding power | Less efficient; continuous energy use |

| Actuation Speed | Fast response times, suitable for high-cycle applications | Slower opening; more gradual due to steady current |

| Operating Temperature | Higher heat buildup in frequent use due to initial surge | Minimal heat buildup, more consistent operation |

| Wear and Tear | Can wear faster if shading rings fail; prone to vibrations | Longer lifespan in consistent, steady use |

| Application Suitability | Ideal for high-speed, rapid-cycle systems | Ideal for noise-sensitive, low-speed applications |

| Power Source Compatibility | Standard AC supply (e.g., 24V AC) | Compatible with battery or solar-powered setups (e.g., 12V DC) |

| Installation Complexity | Requires AC-specific parts and considerations for shading rings | Generally simpler setup, especially for low-voltage uses |

Example Product Recommendations by Application

Industrial Applications with High Cycling Frequency

For applications where valves need to open and close rapidly, such as in manufacturing and automated production lines, an AC solenoid valve is typically the best choice. AC valves offer faster actuation and a lower holding power requirement after initial activation, making them efficient for repetitive cycles.

Recommended Product: 1/2" 24V AC Electric Brass Solenoid Valve (Normally Closed)

This normally closed valve is ideal for applications where fluid flow should be stopped when the valve is not powered, ensuring safety in case of a power failure. It is built for durability in high-demand environments, with quick response times and reliable performance.

Low-Noise Environments (Hospitals, Laboratories, Offices)

In noise-sensitive applications like medical facilities or labs, where valve actuation should be as quiet as possible, a DC solenoid valve is preferable. DC valves operate without the buzzing associated with AC valves, making them better suited to maintain a quiet atmosphere.

Recommended Product: 1/2" 12V DC Electric Stainless Steel Solenoid Valve (Normally Closed)

This normally closed valve maintains a closed state without power, making it a good choice for controlled environments where reliable shutoff is essential. Its stainless steel construction ensures durability, and it operates quietly to support noise-sensitive applications.

Water and Fluid Control for DIY or Residential Use

For residential fluid control setups like garden irrigation, water filtration, or small water features, an AC solenoid valve is generally more compatible with standard household wiring. However, for projects powered by alternative sources, such as battery-operated or solar-powered systems, a DC solenoid valve may be a better choice due to its low-voltage compatibility.

Recommended Product for AC Applications: 1/2" 24V AC Stainless Steel Solenoid Valve for Water Applications (Normally Closed)

A normally closed valve ensures that water flow stops when power is off, which is typically safer for residential applications. This valve is compatible with standard AC power setups, making it suitable for various household water control needs. The stainless steel body makes it safe for potable drinking water as well.

Recommended Product for DC or Alternative Power Applications: 3/8" 12V DC Brass Solenoid Valve for Water Applications (Normally Closed)

Designed as normally closed for safety, this valve is perfect for low-pressure systems where a DC power source, like solar or battery, is used. It is ideal for projects such as solar-powered irrigation where flow control is needed only when powered.

Conclusion

Understanding the operational differences between AC and DC solenoid valves is crucial for making an informed decision that aligns with your application's needs. Consider factors such as response time, power consumption, noise levels, and power supply availability when selecting a solenoid valve.

At Electricsolenoidvalves.com, we offer a comprehensive range of both AC and DC solenoid valves to meet diverse application requirements. Our experienced team is ready to assist you in choosing the perfect valve for your system.

Contact Us Today!

Ready to find the ideal solenoid valve for your application? Contact us to speak with one of our experts or browse our extensive selection of high-quality AC and DC solenoid valves to find the perfect match for your needs.

Additional Resources:

- Solenoid Coil Parameters – Their Effects and Measurement - Explore how factors like resistance, inductance, and impedance impact solenoid coil performance and efficiency, and learn methods for accurately measuring these parameters

- Solenoid Coil Resistance vs Temperature - Understand the relationship between coil resistance and temperature, and discover how temperature variations can affect solenoid valve performance and reliability

- What is a Solenoid Valve? - An introductory guide covering the basics of solenoid valves, including how they work, where they are used, and the advantages they offer in controlling fluid and gas flow

- Frequently Asked Questions (FAQ) About Solenoid Valves - Find answers to common questions about solenoid valves, from usage in various applications to maintenance tips and compatibility with different media types

- Key Components of a Solenoid Valve - A breakdown of the main parts inside a solenoid valve, detailing the function of each component and how they work together to control media flow