Oct 7th 2021

PTFE vs. Teflon

PTFE and Teflon are hugely important to hundreds of industries across the globe. These materials are responsible for the machinery, processing facilities, and automation lines in thousands of places worldwide.

Teflon, unlike PTFE, is a household name. You may likely have a nice non-stick Teflon-coated in your kitchen cabinet. You may not realize that you very likely used PTFE in other places just throughout your own home.

PTFE is a rare term outside of commercial use. Perhaps even if you know what PTFE is, you might wonder how it compares to Teflon. Let’s start with the basics: what is PTFE?

What is PTFE?

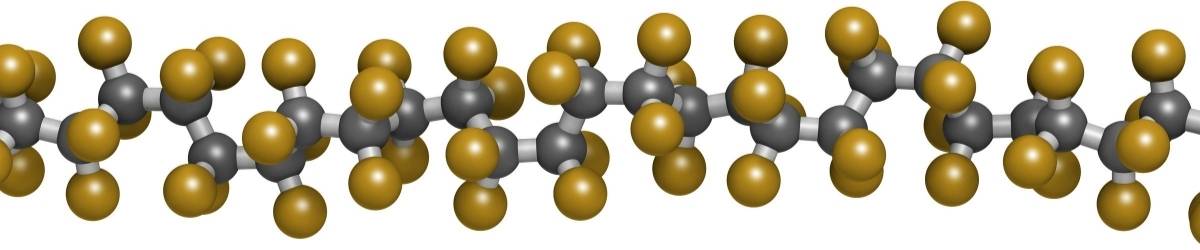

PTFE, or as it is scientifically known: polytetrafluoroethylene, is a synthetic fluoropolymer of tetrafluoroethylene. It’s basically a very tough polymer.

In the United States, PTFE was patented in 1945 and has been an industry essential ever since. The average person will recognize it in such applications as a non-stick coating on cookware, though it has many other uses beyond that.

Chemically speaking, PTFE only consists of carbon and fluorine. It was created by accident by Dr. Roy Plunkett in 1938 when he was trying to improve upon coolant gas. The gas solidified into a slime-like polymer, and Dr. Plunkett noted its remarkable properties.

The following year, it was entered into the Guinness Book of World Records as the “slickest substance” known to man. By 1942 PTFE had found applications in the war effort, including the first atomic bomb. DuPont, the company Dr. Plunkett worked for, registered a trademark in 1945 for their PTFE material.

By 1961, PTFE had found its way onto pans as a revolutionary non-stick coating and into the space race of 1969. Today, people continue to find new uses for this remarkable substance.

The Characteristics of PTFE

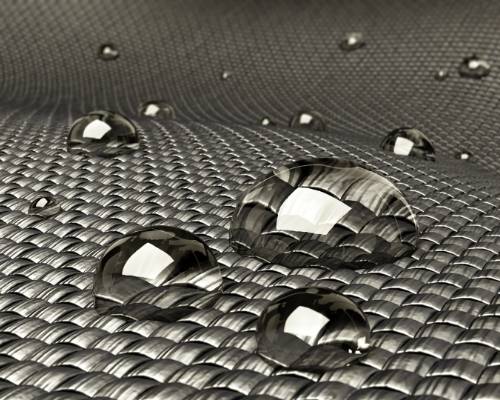

Hydrophobic

- PTFE is not only waterproof, but it also repels all water-based liquids. Its extremely smooth, non-porous surface makes it ideal for various applications, such as acting as a pipeline to transport chemicals.

Almost entirely chemically inert

- PTFE does not react with almost any other chemical substance. Lack of chemical reaction is one of the main reasons it is such a good choice for cookware. Metals like aluminum, for example, easily corrode when they come into contact with acids, such as lemon juice.

High electrical resistance

- PTFE does not conduct electricity very well, making it safe to use around electrical currents.

High dielectric strength

- Similarly, PTFE is dielectric. This property makes it an excellent choice for wiring as it acts as an insulator.

High flexural strength

- PTFE has high flexural strength. Flexural strength means it can bend quite a bit before breaking. Its flexibility gives it more durability and resistance to repeated movements, making it perfect for machine parts and hose linings.

Lowest friction of any solid material

- In combination with its hydrophobic properties, PTFE’s low friction coefficient makes it the ideal material for non-stick cookware, pipelines, and windshield wipers.

Very large temperature operating range

- PTFE has a large temperature range that it can work within. It has a melting point of 327°C and can work down to -200°C (the Teflon melting point and working freezing point are the same).

What is Teflon?

Earlier in the article we mentioned that Dupont acquired a trademark for their PTFE creation in 1945. What was it that Dupont trademarked? Well, the name Teflon™.

Essentially, Teflon is just the brand-name version of PTFE. It’s like the difference between tissues and Kleenex, or cotton swabs and Q-tips. Many people use the brand name Kleenex to refer to any tissue. It’s the same story with Teflon; people say Teflon when talking about any brand of PTFE, whether they realize it or not.

Because of its strong brand recognition, people often associate Teflon with high quality, sometimes paying a premium price for the name without realizing that generic PTFE offers the same properties.

PTFE in Ball Valves and Y Strainers

Ball valves and y strainers are a common components in automotive, oil, gas, chemical processing, and many other industries. They are invaluable tools for controlling pipeline flow. Ball valves can be either manual or electric, but both serve the same purpose.

In ball valves, whether manual or electric, a ball with a hole in the middle rotates to control the flow. When the ball is aligned with the pipe, the opening allows liquid or gas to flow through. Rotating the ball 90 degrees stops the flow, as the solid side of the ball blocks the pipe.

Y strainers, on the other hand, are devices used to remove unwanted solids from liquid, gas, or steam lines by means of a perforated or wire mesh straining element. They are named for their shape, which resembles the letter "Y". The strainer element requires a reliable seal to prevent leaks and ensure efficient filtration.

Using durable materials in ball valves and y strainers ensures the consistent flow of liquid or gas without the threat of leaks or blockages. This is where PTFE comes into play.

Benefits of PTFE in Ball Valve Seats and Y Strainer Seals

The valve seat in ball valves and the seals in y strainers are responsible for sealing fluid within the system and distributing stress uniformly. It's essential to find ball valves and y strainers with components made of a durable and dependable material. PTFE is one of the best materials to incorporate into ball valve seats and y strainer seals due to its outstanding properties, which is why ElectricSolenoidValves.com utilizes this material for our manual and motorized ball valves and y strainers. These benefits include:

The valve seat is responsible for sealing fluid within the valve and distributing stress uniformly. It's essential to find a ball valve with a seat made of a durable and dependable material. PTFE is one of the best materials to incorporate into ball valve seats due to its outstanding properties, which is why ElectricSolenoidValves.com utilizes this material for our motorized ball valves. These benefits include:

Durability Against Harsh Chemicals

Thanks to its chemical inertness, PTFE can withstand exposure to aggressive chemicals without degrading. This makes it ideal for use in valves and strainers that control the flow of corrosive substances.

Low Friction

PTFE's low friction coefficient reduces stem torque in ball valves, making them easier to operate and minimizing wear over time. In y strainers, this property ensures that the seals maintain integrity without excessive wear. This contributes to the sealing ability, allowing for a tighter seal with less force.

Temperature Resistance

PTFE can handle a wide range of temperatures, from cryogenic temperatures up to 550°F (287°C). This makes it suitable for applications involving extreme heat or cold.

Shape Retention During Thermal Expansion

PTFE has the ability to retain its shape even during thermal expansion or temperature changes. This ensures that ball valves and y strainers maintain a proper seal under varying conditions.

Long Service Life

With its excellent ductility and resistance to wear, PTFE offers a long service life, reducing the need for frequent replacements and maintenance.

FDA Approval and Easy Cleaning

PTFE is approved by the FDA for use in food and pharmaceutical applications. Its non-porous surface is easy to clean, making it hygienic for use in sensitive environments.

PTFE vs. Teflon: Is There a Difference?

So, between PTFE and Teflon, who is the winner? Was there even a contest to begin with?

The long and short is that they are the same thing. Teflon is simply a trademarked brand name for PTFE material.

The only notable difference between Teflon and other brands of PTFE is brand recognition. In fact, the marketing around Teflon is so strong that companies need to apply to license the name.

While the material remains the same, the only difference is usually a startling price range between generic PTFE and Teflon. You might end up paying more just for the name, without any additional benefits.

Conclusion

PTFE, or Teflon as many know it, is a remarkable material with a host of beneficial properties. From its chemical inertness and temperature resistance to its low friction and durability, PTFE plays a crucial role in many industries.

In the world of electric ball valves and y strainers, PTFE is an invaluable component that enhances performance and longevity. Its use in valve seats ensures a reliable seal, reduces wear, and handles a wide range of temperatures and chemicals.

So, the next time you come across PTFE or Teflon, you'll know that they're two names for the same incredible material. Whether you're considering cookware or components for industrial applications like electric ball valves, PTFE offers the quality and reliability you can count on.

Looking for High-Quality Electric Ball Valves?

At ElectricSolenoidValves.com, we offer a wide range of manual and electric ball valves and y strainers that incorporate PTFE seats and seals for enhanced performance and durability. If you have any questions or need assistance selecting the right valve or strainer for your needs, our experts are here to help.

Contact us today to learn more about how our PTFE-equipped electric ball valves can benefit your applications.