Jul 3rd 2024

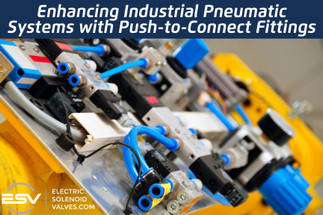

Enhancing Industrial Pneumatic Systems with Push-to-Connect Fittings

Push connect fittings are integral components in industrial pneumatic systems. They are connectors that provide easy and quick means to assemble pipes and tubes conveying air or gasses. These components are suitable for various industrial pneumatic applications, offering multiple advantages over traditionally recognized tubing and piping connection methods.

This article explores the ins and outs of push connect fittings, their unique advantages, typical industrial applications, ways to optimize their compatibility in different residential and commercial applications and best practices to maximize their reliability and longevity. Let us dive deeper into the world of push connect fittings, sometimes commonly known as push-to-connect or instant fittings.

Table of Contents

- How Push Connect Fittings Work

- Benefits of Using Push Connect Fittings in Air Systems

- Applications of Push-to-Connect Fittings

- Ways to Ensure Compatibility of Push Connect Fittings

- Best Practices to Extend the Life and Functionality of Push Connect Fittings

How Push Connect Fittings Work

Push-to-connect fittings have seemingly simple body designs, yet the internal components bear unique features vital for their functionality in pneumatic systems. These connectors also come in different shapes and sizes, ensuring a perfect fit for various pipe and tube sizes. Typically, push connect fittings consist of the following:

- Connector body - fabricated from different materials depending on the intended application area. Predominant connector body materials are plastic, stainless steel, and brass.

- Sealing material - push connect fittings have suitable O-ring or gasket seals that guarantee leak-free fluid service.

- Collet or gripping mechanism - the collet holds the adjacent tubing in place upon assembly. Pressing the collar or release rings in some connectors stops the collet from gripping assembled tubing or pipes, allowing easy disassembly.

- Inlet and outlet ports - allow tubes to be fitted onto the connect fittings. The configuration of these ports varies. Check the different types of push connect fittings that Electric Solenoid Valves stocks here.

Straight union push connect fitting

Assembling a push connect fitting is simple and does not require complex tools. Here is how these components work in pneumatic or industrial air supply applications:

- Insert tubes into the fitting by pushing them through the inlet and outlet ports of the fitting.

- When inserting the tubes, they compress the O-rings within the push connect fitting. This process creates a leak-tight seal, ensuring no gasses escape around the fitting’s body.

- Once the tube sits tightly against the seal and the internal parts of the fittings, specially designed teeth of the fitting’s collet grip tightly against the outer surfaces of the tubing. The grip is sufficient to keep the tubing in place and does not interfere with fluid flow through the fitting and between adjacent tubes.

- Releasing the tube from the fitting is equally straightforward. One pushes the collar of the fitting or release button on some push connect fitting designs. Pushing the collar loosens the collet, which withdraws the grip on the outer surfaces of the tubes. One can then pull out the tubes from the fitting.

Benefits of Using Push Connect Fittings in Air Systems

Push connect fittings are preferable for most air handling and pneumatic applications because of their easy assembly and disassembly capabilities. Installing them in pre-existing service lines is quick. One does not require expensive tools to manage their assembly and disassembly - and is preferable over connectors that may require additional tools like crimping accessories, wrenches and soldering or welding machines.

Push connect fittings are versatile and reusable. They are compatible with different materials, including nylon, polybutylene, polyurethane, copper, chlorinated polyvinyl chloride (CPVC), and PEX, among other tube materials. They are also reusable, meaning one can utilize them as fittings for various tubing and piping operations without wear and tear. They are a cost-effective alternative for tube connections requiring frequent connection and disconnection. They are available in multiple configurations to suit different use case scenarios.

Push connect fittings have excellent sealing properties. They provide reliable defenses against media leakage, enhancing overall system efficiency. Additionally, these fittings have remarkable safety standards. First, their designs make incorrect assembly difficult. Second, their leak-proof sealing mechanisms prevent media leakage. Media leakage can be a catalyst for accidents in industries and residential premises.

Push-to-connect pipe fittings have compact designs. It implies they are usable in tight spaces. They are designed to last long, employing robust materials that withstand rapid wear, tear and corrosion from the service media and the immediate environment.

Branch Tee Connector Push Connect Fitting

Applications of Push-to-Connect Fittings

Push-to-connect fittings are versatile, and their applications cut across industries. Here is a look at some practical application areas of push connect fittings.

Compressed Air Systems

Compressed air is a critical component in different industrial applications. It can perform various functions ranging from simple tasks like blow-off cleaning to more complex operations like powering automated industrial tools and machinery. All these operations require tubing or piping, making push connect fittings an integral part of the compressed air system design.

Here are a few areas where push connect fittings are utilized in compressed air systems.

- Compressed air distribution systems - connecting hoses and tubes for distributing air from the compressors to dedicated use points across a facility.

- Industrial air treatment systems - push connect fittings are found in specialized systems for treating air for special industrial operations demanding clean air. The connectors are found in air treatment elements like air dryers, filters, and regulators.

- Compressed air instrumentation - push connect fittings are vital for connecting pneumatic instruments and auxiliary control devices in complex industrial systems. Fittings in such instrumentation systems contribute to precise airflow control.

Air Tools and Pneumatic Machinery

Air tools and pneumatic machinery use air to perform their functions. These tools have optimal power-to-weight ratios and thus are applicable in different industries. These tools are equally relevant in high-risk environments where electrical tools pose significant risks. That can include areas where flammable materials are present or wet work environments. Examples of air tools include impact wrenches, air hammers, pneumatic conveyors, and actuators. Push connect fittings are popular with the following air tools and pneumatic machinery.

- Assembly line connections - the fittings connect to tubing of various assembly line tools. They can feature connections to tools like air wrenches, pneumatic drills, and pneumatic grippers for material handling on the assembly lines.

- Industrial automation systems - push connect fittings are integral for connecting automation systems to dedicated air supply lines. They are common for connecting pneumatic cylinders, actuators, and automated machinery like robots and cobots.

- Industrial maintenance tools - push-to-connect fittings are essential for maintaining industrial systems. The connectors are vital for connecting pneumatic tools to air supply during maintenance, facilitating quick repair work.

Inline Air Flow Speed Control Valve Push Connect Fittings

Plumbing and HVAC Systems

Plumbing and HVAC systems handle gasses and liquids. Push connect fittings solve some connection problems in select plumbing and HVAC systems. Some notable applications of push connect fittings in these systems are:

- Heating systems - push connect fittings are used to create connections between distribution pipes of radiators, boilers, and other heating equipment.

- Air conditioning systems - they connect refrigerant lines to

various components of the HVAC systems. For example, creating a piped connection between an outdoor HVAC compressor and an indoor vent.

- Plumbing systems - push connect fittings are viable for select plumbing applications. They can create temporary connections for pipes supplying water to faucets, sanitary appliances, and toilets. The connectors are handy when retrofitting aging plumbing systems or conducting routine maintenance on residential water supply lines.

Ways to Ensure Compatibility of Push Connect Fittings

Identifying a push connect fitting, like any other flow control device, requires utmost care and evaluating prevailing fluid conditions. One must ascertain that the preferred fitting is compatible with the service media and the conditions of the operating environment. Proper fitting selection is critical for ensuring optimal performance and averting system issues like leakages, which negatively impact the reliability and efficiency of industrial pneumatic systems. Here is how to match your push connect fitting with the intended applications.

- Ensure fitting compatibility with the service media and adjacent pipes or tubing. Is the pipe system conveying gasses, water or chemicals? Will the push connect fitting suffer wear and tear when interacting with the service fluid? One should also ensure the fitting is compatible with the materials of the pipe. Some pipe materials may accelerate chemical wear and tear of push connect fittings when they come into contact.

- The connector size should match those of the adjacent pipes or tubes. Choose a fitting whose diameter matches those of the pipes in the systems. Failure to match pipe and fitting sizes means the connections created during assembly might be too loose or tight. It can lead to leakages or cause physical damage to internal fitting components. The configuration of the push connect fitting should also match the configuration and layout of the piping system. A straight push connect fitting is unsuitable in a branching pipe layout where a T-fitting or an elbow fitting will be more reliable.

- The selected push connect fitting should meet or exceed the pressure and temperature ratings of the existing system. Choosing a connector whose pressure rating is below the designed value means it cannot withstand flow conditions, exposing the entire system to the risk of failure and lowering overall flow reliability and efficiency.

Elbow Union Push Connect Fitting

Although push connect fittings are designed for easy connection and disconnection, people still make a few mistakes when selecting and handling these connectors. Usually, people overlook material properties, system pressure and temperature ratings and ignore sizing requirements. Failure to take precise pipe measurements may lead to loose connections, detrimental to system safety and efficiency. Sometimes, system designers may fail to include thermal expansion and contraction metrics when choosing push connect fittings. Such thermal changes can compromise the sealing capabilities of these fittings.

Best Practices to Extend the Life and Functionality of Push Connect Fittings

While push-to-connect fittings are easy to use and reliable, they require proper care and frequent maintenance to extend their life and ensure optimal functionality and reliability. These components do not demand extensive maintenance interventions. However, one should perform various proactive maintenance measures to keep these components in good operating conditions and ensure uninterrupted fluid flow through the connectors. Here are a few tips to care for push connect fittings:

- Adhere to manufacturer guidelines when installing push connect fittings. Following these instructions ensures pipe connections created with these fittings have proper seating and sealing for efficient fluid flow.

- Perform an initial compatibility test after installation. Check if the fittings work as intended before subjecting them to full-scale flow conditions. Check connections for any signs of leakage or strain from fluid flow.

- Avoid excessive force when connecting or disconnecting push connect fittings. Proper handling is essential for keeping connector components in good working conditions.

- Perform regular visual inspection on push connect fittings. Check for signs of leaks, surface wear and tear and verify the tightness of connections.

- Keep fittings clean. Remove dirt and debris build-up from the fittings frequently to maintain flow efficiency and push connect fitting integrity.

Push connect fittings have an uncomplicated design, which is beneficial for its functionality. These fittings are prone to two issues. They are:

- Media leakage

- Wear and tear

Troubleshooting these performance issues is straightforward.

Identify the source of the media leakage. Leakages can occur due to improper fitting connections or physical damage due to wear and tear. Try re-seating the fitting and observe if the leakage persists. If this does not solve the problem, replace the push connect fitting with its suitable alternative.

Continuously monitor the push connect fittings for visible signs of wear and tear. Wear can manifest as corrosion and surface cracks. Replace any fittings exhibiting wear and tear before they fail and cause detrimental effects on the reliability of pneumatic systems.

90 Degree Male Elbow Connector Push Connect Fitting

Final Words

Push connect fittings are reliable connectors for multiple pneumatic systems across industries. They have simple, plug-and-play designs and are available in various sizes and configurations, fit for several applications. Proper handling and maintenance are essential for extending the life and efficiency of these fittings. Electric Solenoid Valves stocks various push connect fittings, offering a suitable solution for any pneumatic fitting needs. Our team will help you choose the best fitting for your residential, industrial or DIY push connect fitting needs.