Aug 5th 2024

Troubleshooting Common Electric Ball Valves Issues

Electric ball valves are certainly one of the most important devices of fluid systems—from home automation to industrial settings. As with any mechanical device, they can develop problems over time. This troubleshooter guide will help you identify and troubleshoot common problems with electric ball valves.

About Electric Ball Valves

Electric ball valves control liquid and gas flows by means of a motor rotating a ball with a hole drilled inside. When the hole lines up with the flow, then the valve is fully open; when it is turned perpendicular to the flow, it is closed.

Electric ball valves control liquid and gas flows by means of a motor rotating a ball with a hole drilled inside. When the hole lines up with the flow, then the valve is fully open; when it is turned perpendicular to the flow, it is closed.

The main components of an electric ball valve include the valve body, actuator, ball, and seal.

Common Electric Ball Valves Issues

Below are 4 of the most common issues you might come across when operating a motorized ball valve. They include easy troubleshooting steps that you can perform before needing to reach out to a professional.

Issue: The Valve Isn’t Opening or Closing

Troubleshooting and Fixes

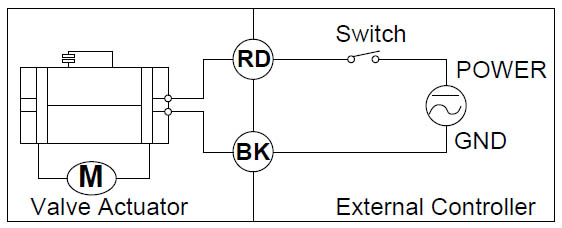

- Power Supply: Check that the power source is functioning and the wiring is connected correctly. If the valve is powered by a controller, verify the controller is sending the correct signal.

- Actuator Failure: The valve will not be able to open or close if your actuator isn't working. Inspect the actuator for damage and listen for any unusual noises while the valve is operating. If the actuator is faulty, you may need to replace it.

- Obstruction: Debris or foreign objects can obstruct the valve's movement. Inspect the internal components and remove any obstructions that you find.

Issue: The Valve Operates Slowly or Erratically

Troubleshooting and Fixes

Troubleshooting and Fixes

- Low Voltage: Low voltage can cause sluggish or erratic valve behavior. Measure the voltage at the valve's terminals. Check the power source and wiring for any issues if the voltage is lower than what the manufacturer's specs say.

- Friction: Insufficient lubrication can cause friction and slow movement. Follow the manufacturer's recommendations for lubrication type and frequency.

- Electrical Interference: Nearby equipment can disrupt the electronics inside of a valve. If this appears to be your problem, relocate the valve and/or install shielding.

- Valve Wear: Excessive wear on components can affect the speed of the valve opening and closing Inspect the moving parts of the valve for any wear or damage that may be causing the parts to stick. Replace damaged parts if possible.

Issue: Leaks and Seal Problems

Troubleshooting and Fixes

Troubleshooting and Fixes

- Worn Seals: Valve seals will wear out over time, leading to leaks. If you find any leaks inspect the valve seals for any signs of damage or excessive wear and replace any damaged seals.

- Loose Connections: Leaks often occur when connections between parts are left too loose. This can happen during installation or naturally over time. Make sure the connections (valve body, actuator, and piping) are tight enough to create proper seals.

- High Pressure: Excessive pressure is another potential cause of leaks. Check the pressure rating of your valve and make sure it is compatible with your application. If the pressure in your system is too high for it, consider installing a pressure regulator or a valve capable of handling higher pressure.

- Improper Installation: Incorrect installation can cause misalignment and seal damage. Check the alignment and secure all components to prevent future leaks.

Issue: The Valve Overheats

Troubleshooting and Fixes

- Overload: A valve that is consistently operating beyond its rated capacity can overheat. Check its specs to determine if it might be getting overloaded. If necessary, upgrade to a larger valve or reduce the load.

- Inadequate Ventilation: Poor ventilation can lead to overheating. Install the valve in a well-ventilated area without obstructions to airflow.

- Faulty Thermostat: If the valve is equipped with a thermostat, the valve may overheat if it is malfunctioning. Test the thermostat and replace it if you find that it's faulty.

Additional Troubleshooting Tips

Advanced Diagnostics:

- Multimeter Use: Learn how to use a multimeter to check electrical continuity and voltage levels in the valve's circuitry.

- Signal Testing: Verify that control signals from automated systems are correctly reaching the actuator.

Visual Inspection:

- Regular Monitoring: Perform regular visual inspections of the valve and surrounding components for any signs of wear, corrosion, or damage.

- Component Comparison: Compare old and new parts to detect subtle differences that might indicate wear or damage.

Preventive Maintenance Tips

Maintaining your valves won’t fix most existing problems, but it can help prevent them from occurring in the future.

Regular Inspection and Cleaning

Regularly inspect and clean your electric ball valves to prevent buildup and keep it operating smoothly.

Proper Installation

Follow manufacturer guidelines during installation to avoid common mistakes.

Install Y-Strainers

Y-strainers can be installed upstream from your ball valve to prevent debris and solid materials from clogging or damaging your valve.

Recommended Maintenance Schedule

Create and follow a maintenance schedule that includes periodic checks and servicing.

Conclusion

Maintaining your electric ball valves is important for keeping your systems up and running. If you know what can go wrong and how to fix it, you avoid wasting precious production time and ensure a long life for your valves. Regular maintenance and professional help when required will keep your systems running without a hitch.

Fast Shipping, Expert Advice

Don't let valve issues slow you down – explore our extensive selection of high-quality electric ball valves today and experience the difference that reliable, efficient valves can make in your operations. With our fully stocked warehouse, we offer fast shipping – your order will be dispatched within one business day.

Not sure which valve is right for you? Our team of valve experts is standing by to answer your questions and provide personalized recommendations. Visit our website or contact us now to find the perfect valve solution for your needs.