May 10th 2024

Guide to Valve Seal Materials: Viton, PTFE, NBR, and EPDM

In this article we will cover:

- The importance of a quality valve seal

- Types of seals used in valves, their purpose, and types of valves they are found in

- Common valve seal materials, including advantages and disadvantages, chemical resistance, key properties, and usage scenarios

Why do Valve Seals Matter?

Valve seals play a pivotal role in the functionality and product life of valves. Faulty or incompatible seals can cause major problems in a fluid or gas system. Below are the key reasons a quality seal matters in a valve.

- Leak Prevention: Leaks will waste fluids, can be hazardous, and cost you money.

- Efficiency: Even small leaks disrupt pressure or flow rates, impacting efficiency.

- Safety: In applications with hazardous chemicals or high temperatures, a failed seal creates major safety risks.

- Valve Longevity: The right seal material will extend the service life of your valve, reducing downtime and replacement costs.

Seal Types - Understanding the Terminology

- Seal: A general term for any component that prevents fluid transfer between joined parts of the valve. Each of the components below can be considered “seals.”

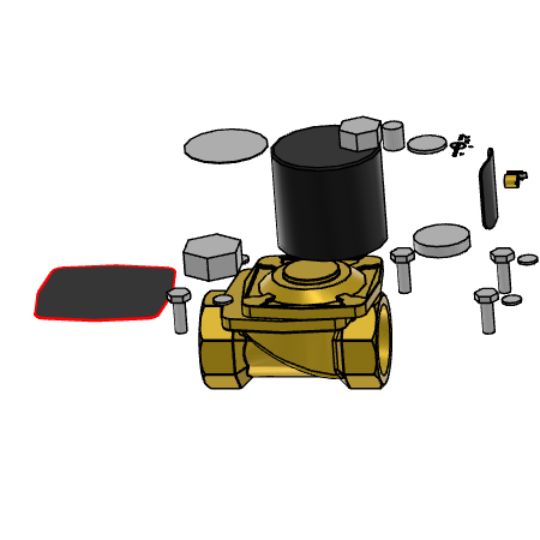

- Gasket: A flat, compressible sealing component that fits between two surfaces, such as the valve body halves.

- Plug Gasket: Installed in check valves to seal the moveable plug.

- End Seal: Gasket found where the valve connects to piping.

- O-ring: A ring-shaped seal, usually made of elastomers, that is used in moving parts or connection points.

- Ball Seat: A ring-shaped component that surrounds the ball in a ball valve, which creates a seal when the valve is closed.

- Stem Packing: A compressed seal around the valve stem that prevent leaks between the stem and the valve body.

- Diaphragm: A flexible membrane, often made of elastomers, that is a key part of the actuation mechanism in some solenoid valves.

Valve Seal Materials

Viton (FKM):

Fluoroelastomers. A synthetic rubber with excellent chemical resistance to oils, fuels, and chlorinated solvents.

- Advantages: Excellent resistance to chemicals and high temperatures

- Disadvantages: High cost, less flexible at low temperatures

- Common Applications: Chemical processing, oil & gas, valves handling aggressive fluids

Valve Examples:

3-way brass electric ball valves with Viton seals

Brass electric ball valves with Viton sealsBrass solenoid valves with Viton diaphragms

PTFE (Teflon):

Polytetrafluoroethylene. A thermoplastic fluoropolymer, created by Dupont known for its use on non-stick kitchenware.

- Advantages: Supreme chemical resistance, very low friction

- Disadvantages: Lower mechanical strength, prone to creep (deformation under load)

- Common Applications: Food & beverage, sanitary applications, highly corrosive substances

Valve Examples:

Swing check valves with PTFE plug gasket

Vertical check valves with PTFE end seal

Manual ball valves with PTFE ball seats, thrust washers, stem packings

Stainless steel steam solenoid valves with PTFE seal

NBR (Nitrile Rubber):

Nitrile butadiene rubber, NBR, Buna-N. An oil/fuel-resistant synthetic rubber.

- Advantages: Good oil and petroleum resistance, versatile

- Disadvantages: Limited chemical resistance, degrades at higher temperatures

- Common Applications: Hydraulics, pneumatics, general-purpose valves

Valve Examples:

Pneumatic solenoid valves with NBR O-rings

Low pressure gas solenoid valves with NBR diaphragms

3-way brass solenoid valves with NBR seals

EPDM:

Ethylene propylene diene rubber. A synthetic rubber, commonly used for valve diaphragms, gaskets, and O-rings.

- Advantages: Excellent for water, steam, and mild chemicals

- Disadvantages: Poor resistance to oils and hydrocarbons

- Common Applications: Water treatment, irrigation systems, steam valves

Valve Examples:

Plastic zero differential solenoid valves with EPDM diaphragms

Plastic 2-way solenoid valves with EPDM seals

Additional Considerations

Valve Design: The design of the valve impacts the seal selection. For instance, ball valves use ball seats and stem seals while diaphragm valves have a a flexible diaphragm material. The structure of the seal and the anticipated uses will help determine the material the seal is made of.

Regulatory Standards: For industries with strict material standards like food production (FDA), pharmaceutical (USP), or potable water (NSF), material compliance is a requirement. Always check the regulations and compare them to the components of the valve before installing.

Material Compatibility: Each of the different kinds of material used to make valve seals have different chemical compatibility. Below is a quick compatibility chart that illustrates which materials are suitable for various fluids and gases. For a more complete list, see our chemical compatibility database.

| Material | Water | Oil | Gas | Acids |

|---|---|---|---|---|

| Viton | Good | Excellent | Fair | Good |

| PTFE | Excellent | Good | Excellent | Excellent |

| NBR | Fair | Excellent | Fair | Poor |

| EPDM | Excellent | Poor | Good | Fair |